Sprayable Peptide Amphiphile Nanofibers: A Revolutionary Biomaterial for Advanced Wound Healing

This article comprehensively reviews the development, application, and therapeutic potential of sprayable peptide amphiphile (PA) nanofibers for wound management.

Sprayable Peptide Amphiphile Nanofibers: A Revolutionary Biomaterial for Advanced Wound Healing

Abstract

This article comprehensively reviews the development, application, and therapeutic potential of sprayable peptide amphiphile (PA) nanofibers for wound management. Targeting researchers, scientists, and drug development professionals, we explore the foundational chemistry of PA self-assembly into bioactive nanofibers that mimic the native extracellular matrix. The scope covers molecular design principles, innovative sprayable delivery methodologies that enable in-situ gelation, and optimization strategies to overcome translational challenges. We further present rigorous preclinical validation data and comparative analyses with conventional wound therapies, highlighting the significant enhancement in healing outcomes for burns and chronic wounds. This synthesis aims to inform future research and accelerate the clinical adoption of this transformative nanotechnology.

The Molecular Blueprint: Understanding Peptide Amphiphile Self-Assembly and Bioactivity

Core Molecular Structure of Peptide Amphiphiles

Peptide amphiphiles (PAs) are a class of peptide-based molecules that combine the structural features of amphiphilic surfactants with the functions of bioactive peptides [1]. These molecules are designed to self-assemble into a variety of supramolecular nanostructures, including high-aspect-ratio nanofibers, which are of significant interest for wound healing applications [1] [2]. The canonical structure of a peptide amphiphile, as developed in foundational research, comprises four distinct key segments [1] [2]:

- 1. Hydrophobic Domain: This region typically consists of a long alkyl tail (e.g., palmitic acid with 10-16 carbons) and serves as the primary driver for the self-assembly process via the hydrophobic effect [1] [2].

- 2. β-Sheet Forming Sequence: Adjacent to the hydrophobic segment, this region consists of a short sequence of hydrophobic amino acids with a strong propensity to form intermolecular hydrogen bonds, stabilizing the resulting one-dimensional nanostructure [1].

- 3. Charged Amino Acids: This hydrophilic segment contains ionizable residues (e.g., aspartic acid, glutamic acid, lysine) that enhance the PA's solubility in aqueous solutions and allow for the design of systems responsive to pH and ionic strength [1] [2].

- 4. Bioactive Epitope: The terminal region of the peptide sequence is functionalized with a bioactive signal (e.g., RGD, IKVAV) designed to interact with cells or proteins, imparting specific biological functions to the self-assembled material [1] [2].

Table 1: Core Segments of a Canonical Peptide Amphiphile Molecule

| Segment Number | Segment Name | Core Function | Common Molecular Components |

|---|---|---|---|

| 1 | Hydrophobic Domain | Drives self-assembly via hydrophobic collapse | Alkyl tail (e.g., palmitic acid, C16) |

| 2 | β-Sheet Forming Sequence | Enforces nanofiber geometry via H-bonding | Repetitive sequences like VVVAAA or (SL)6 |

| 3 | Charged Amino Acids | Confers water solubility & triggers assembly | Aspartic acid, Glutamic acid, Lysine |

| 4 | Bioactive Epitope | Elicits specific biological responses | RGD (cell adhesion), IKVAV (neurite outgrowth) |

Molecular Self-Assembly into Nanofibers

The self-assembly of PAs into nanofibers is a hierarchical process. In an aqueous environment, the hydrophobic tails aggregate to minimize their contact with water, forming the core of the structure. Simultaneously, the β-sheet-forming sequences align and create a network of hydrogen bonds, forming the cylindrical wall of the nanofiber. This arrangement positions the charged residues and, crucially, the bioactive epitopes on the exterior surface of the fiber, making them available for biological interactions [1]. This assembly can be triggered by a physiological stimulus, such as the presence of salts in bodily fluids, making PAs excellent candidates for injectable or sprayable therapies that gel in situ [1] [2].

Protocol: Fabrication of Sprayable PA Nanofiber Hydrogels for Wound Healing

This protocol details the synthesis, self-assembly, and in vitro characterization of a bioactive PA hydrogel designed for sprayable wound healing applications. The model PA incorporates the IKVAV epitope, known for promoting neurite outgrowth and wound repair [1].

Materials and Reagents

Table 2: Essential Research Reagents and Materials

| Item Name | Function/Application | Exemplary Supplier/Part Number |

|---|---|---|

| Palmitic Acid | Hydrophobic tail component for PA synthesis | Sigma-Aldrich, P0500 |

| Rink Amide MBHA Resin | Solid support for peptide synthesis | AAPPTec, SP-1000 |

| Fmoc-Protected Amino Acids | Building blocks for peptide sequence | AAPPTec or ChemPep |

| IKVAV Peptide Epitope | Bioactive signal for promoting wound healing | Custom synthesis required |

| Dulbecco's Phosphate Buffered Saline (DPBS) | Physiological trigger for self-assembly | Thermo Fisher, 14190144 |

| Dichloromethane (DCM) | Solvent for resin washing | Sigma-Aldrich, 270997 |

| N,N-Dimethylformamide (DMF) | Solvent for peptide synthesis | Sigma-Aldrich, 227056 |

| Trifluoroacetic Acid (TFA) | Cleavage cocktail component for resin cleavage | Sigma-Aldrich, T6508 |

| Diethyl Ether | Solvent for PA precipitation | Sigma-Aldrich, 309966 |

Step-by-Step Experimental Procedure

Part A: Solid-Phase Peptide Synthesis of the PA Molecule

- Resin Swelling: Place 0.5 g of Rink Amide MBHA resin (loading: 0.5 mmol/g) into a solid-phase peptide synthesis (SPPS) reactor. Swell the resin with 10 mL of DCM for 30 minutes with gentle agitation.

- Fmoc Deprotection: Drain the DCM and treat the resin twice with 10 mL of 20% (v/v) piperidine in DMF (5 min per treatment) to remove the Fmoc protecting group.

- Coupling Cycle: After thorough washing with DMF (5 x 10 mL), add 4 equivalents of the first Fmoc-protected amino acid, 4 equivalents of HBTU, and 8 equivalents of N,N-Diisopropylethylamine (DIPEA) in DMF. React for 45-60 minutes with agitation.

- Sequence Elongation: Repeat steps 2 and 3 for each amino acid in the sequence: C16-VVVAAAEEEE-IKVAV (from C- to N-terminus).

- Palmitoylation: After the final Fmoc deprotection, couple palmitic acid (4 eq) using HBTU/DIPEA activation overnight.

- Cleavage and Deprotection: Cleave the PA from the resin and remove side-chain protecting groups using a cocktail of TFA:Triisopropylsilane:Water (95:2.5:2.5) for 3 hours.

- Precipitation and Purification: Precipitate the crude PA in cold diethyl ether, collect by centrifugation, and purify via reversed-phase HPLC. Lyophilize the pure fractions to obtain a white fluffy solid.

Part B: Preparation and Characterization of the Sprayable Hydrogel

- Stock Solution Preparation: Dissolve the purified PA in sterile, deionized water to a final concentration of 1.0% (w/v). Adjust the pH to 7.4 using a dilute NaOH solution. Sterilize the solution by passing it through a 0.22 µm filter. Note: The solution should remain clear and have low viscosity at this stage.

- Gelation Triggering (Spray Simulation): Load the PA solution into a spray device (e.g., an airbrush system). Spray the solution onto a sterile surface from a distance of 10-15 cm. Simultaneously, mist the stream with a simulated physiological buffer (e.g., 150 mM NaCl or DPBS) to trigger instantaneous gelation upon contact.

- Rheological Characterization: To quantify mechanical properties, induce gelation in situ on the plate of a rheometer by adding 20 µL of 10x DPBS to 180 µL of the PA solution. Perform a time sweep experiment at 1 Hz frequency and 1% strain to monitor the storage (G') and loss (G'') moduli over time.

Quality Control and Functional Assay

- Critical Aggregation Concentration (CAC): Determine the CAC using a pyrene fluorescence assay. The CAC is typically in the low micromolar range (e.g., 5-20 µM) for effective PAs [1].

- Cytocompatibility (ISO 10993-5): Culture human dermal fibroblasts (HDFs) in the presence of PA hydrogel extracts. Assess cell viability after 24 hours using a standard MTT assay. A viability >90% relative to the control is considered non-cytotoxic.

- In Vitro Wound Healing Assay: Create a scratch wound in a confluent monolayer of HDFs. Monitor wound closure over 48 hours in the presence of the PA hydrogel or its eluent compared to a control. Calculate the percentage of wound closure at 12, 24, and 48-hour time points.

Table 3: Key Quantitative Parameters for a Functional PA Hydrogel

| Parameter | Target Value/Range | Analytical Method |

|---|---|---|

| PA Purity | >95% | Analytical HPLC |

| Critical Aggregation Concentration (CAC) | 5 - 20 µM | Pyrene Assay |

| Gelation Time | < 60 seconds | Visual test / Rheometry |

| Storage Modulus (G') | 100 - 5000 Pa | Oscillatory Rheometry |

| Fibroblast Viability | >90% | MTT Assay |

| IKVAV Density on Fiber | ~ 10^15 epitopes/cm² | Calculated from structure [1] |

Application Notes and Troubleshooting

- Bioactivity Failure: If the final PA gel lacks the expected bioactivity, verify the integrity of the bioactive epitope after synthesis via mass spectrometry. The epitope may be susceptible to degradation or improper folding during synthesis.

- Insufficient Gel Strength: If the hydrogel is too weak, consider increasing the length of the β-sheet forming segment or the alkyl tail to enhance intermolecular interactions. Alternatively, increase the overall PA concentration.

- Slow Gelation Kinetics: For a sprayable system, rapid gelation is critical. If gelation is too slow, pre-mix the PA solution with a minimal volume of a concentrated salt solution immediately before the spray nozzle, or use a dual-spray system that mixes the streams upon ejection.

- PA Precipitation: If the PA precipitates instead of forming a gel upon salt addition, the charged segment might be too short. Redesign the PA to include additional charged residues to improve solubility before assembly.

Supramolecular chemistry, famously termed "chemistry beyond the molecule," provides the foundation for designing highly organized systems across multiple length scales without covalent bonds [3]. This approach is particularly powerful in creating biomaterials for regenerative medicine, where peptide amphiphiles (PAs) have emerged as a versatile platform for constructing nanofibrous structures that emulate the native extracellular matrix (ECM) [3] [4]. These self-assembled nanostructures are exceptionally suitable for wound healing applications, as they can be designed to display bioactive signals, deliver therapeutic payloads, and assemble into injectable or sprayable hydrogels that conform to complex wound beds [5] [4]. The dynamic and reversible nature of supramolecular interactions enables the creation of smart materials that can respond to physiological cues, making them ideal for advanced therapeutic strategies in skin regeneration and repair [3] [6].

Molecular Design of Peptide Amphiphiles

The structural blueprint of peptide amphiphiles follows a modular domain approach, with each segment playing a distinct role in the self-assembly process and biological function [3] [7]. A typical PA molecule incorporates four key regions that work in concert to drive nanofiber formation and bioactivity.

- Hydrophobic Domain: This segment typically consists of a long alkyl tail (often derived from palmitic acid) that drives the hydrophobic collapse and forms the core of the nanofiber. This domain is crucial for the amphiphilic character of the molecule [3].

- β-Sheet Forming Sequence: Adjacent to the alkyl tail, a short peptide sequence with a strong propensity to form intermolecular hydrogen bonds promotes the formation of β-sheets. The principal axes of these β-sheets run parallel to the long axis of the nanofiber, governing the one-dimensional growth into high-aspect-ratio nanostructures [3].

- Charged Segment: This region contains acidic or basic amino acids that provide electrostatic repulsion in solutions of low ionic strength, ensuring adequate solubility and preventing premature assembly. This design enables triggered self-assembly upon exposure to physiological electrolytes, facilitating injectable or sprayable formulations that gel at the wound site [3] [5].

- Bioactive Epitope: The terminus opposite the hydrophobic tail is functionalized with a bioactive peptide signal (e.g., RGDS or IKVAV) that interacts with cellular receptors. This epitope is displayed on the nanofiber surface at high density, enabling the material to directly signal cells and influence their behavior [3] [7].

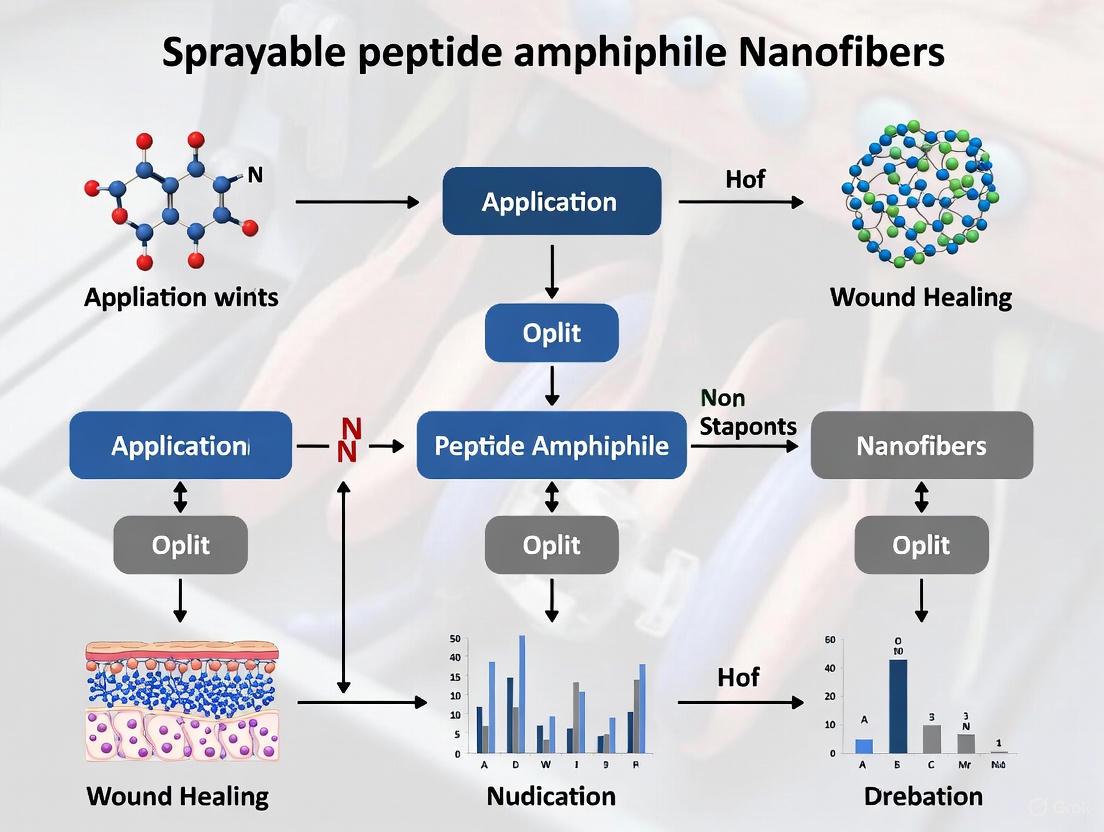

The following diagram illustrates the logical relationship between the molecular structure of a peptide amphiphile and its hierarchical assembly into a bioactive nanofiber network suitable for wound healing.

Key Characterization Data for PA Nanofibers

Rigorous characterization is essential to confirm the successful synthesis of PA monomers and their subsequent assembly into the desired supramolecular structures. The following data, derived from established protocols, provides benchmarks for key physical and biological properties.

Table 1: Quantitative Characterization Data for Peptide Amphiphile Nanofibers

| Characterization Method | Key Parameters Measured | Typical Results/Output |

|---|---|---|

| Liquid Chromatography-Mass Spectrometry (LC-MS) | Molecular weight, purity of PA monomers | Confirmation of exact mass; purity >95% often required for biological applications [5]. |

| Circular Dichroism (CD) | Secondary structure, internal ordering during assembly | Characteristic minimum at ~218 nm indicating β-sheet formation [5]. |

| Transmission Electron Microscopy (TEM) | Nanofiber morphology, diameter, length | High-aspect-ratio cylindrical nanofibers; diameters ~6-10 nm [3] [5]. |

| Rheology | Storage modulus (G'), loss modulus (G"), gelation time | Shear-thinning behavior; G' > G" indicating solid-like gel behavior; gelation via ionic crosslinking [5]. |

| Cell Viability Assay (e.g., LDH) | Biocompatibility, cytotoxicity | >90% cell viability confirmed in human embryonic kidney cells [5]. |

| Endothelial Cell Tube Formation Assay | Angiogenic potential | Significant increase in tubule length and branch points compared to controls [5]. |

Table 2: Biological Performance of PA Nanofibers in Wound Healing Models

| Bioactive Signal | Experimental Model | Key Healing Outcomes |

|---|---|---|

| RGDS | In vitro thermally damaged human fibroblasts (hFBs) and human umbilical vein endothelial cells (HUVECs) | Significant stimulation of cell proliferation and migration [7]. |

| RGDS | In vivo rat burn model | Accelerated burn wound closure; stimulation of fibroblast and epithelial cell proliferation [7]. |

| Pro-angiogenic PA | In vitro endothelial cell tube formation assay | Enhanced blood vessel formation, indicating promise for treating deep dermal burns [5]. |

Experimental Protocols

The following protocols detail the essential procedures for the preparation, characterization, and functional testing of peptide amphiphile nanofibers for wound healing applications.

Protocol: Solid-Phase Synthesis of Peptide Amphiphiles

This protocol describes the synthesis of peptide amphiphiles using solid-phase peptide synthesis (SPPS), which allows for the sequential addition of protected amino acids while the growing chain is anchored to an insoluble resin [5] [8].

- Resin Loading: Begin with a rink amide resin (loading capacity: ~0.5 mmol/g). Place the resin in a solid-phase reaction vessel. Deprotect the Fmoc group by treating the resin with 20% piperidine in DMF (2 x 10 mL, 5 min each).

- Amino Acid Coupling: For each amino acid in the sequence (starting from the C-terminus), perform the following:

- Wash the resin with DMF (3 x 10 mL).

- Prepare a coupling mixture of Fmoc-protected amino acid (4 equiv.), HBTU (3.9 equiv.), and HOBt (3.9 equiv.) in DMF. Add DIPEA (8 equiv.) to activate the amino acid.

- Add the coupling mixture to the resin and agitate for 1-2 hours at room temperature.

- Wash the resin with DMF (3 x 10 mL) after coupling is complete.

- Remove the Fmoc protecting group with 20% piperidine in DMF (2 x 10 mL, 5 min each) before the next coupling cycle. Confirm deprotection by a Kaiser test.

- Alkylation: Following the completion of the peptide sequence, couple palmitic acid (4 equiv.) using the same coupling reagents and protocol (HBTU/HOBt/DIPEA) to form the hydrophobic tail [3].

- Cleavage and Deprotection: After the final Fmoc deprotection, wash the resin with DCM (3 x 10 mL). Cleave the peptide amphiphile from the resin and remove side-chain protecting groups using a cleavage cocktail (e.g., TFA:TIS:Water, 95:2.5:2.5, 3 mL per 100 mg resin) for 3 hours with gentle agitation.

- Precipitation and Purification: Filter the cleavage mixture and precipitate the crude PA in cold diethyl ether. Centrifuge to collect the pellet. Purify the PA via reverse-phase high-performance liquid chromatography (RP-HPLC). Analyze the final product using LC-MS to confirm molecular weight and purity [5].

Protocol: Self-Assembly and Gelation of PA Nanofibers

This protocol triggers the self-assembly of PA monomers into nanofibers and the subsequent formation of a hydrogel network, suitable for creating a sprayable wound dressing [3] [5].

- Preparation of Aqueous PA Solution: Dissolve the purified PA in ultrapure water (e.g., 1% w/v) by gently vortexing and/or brief sonication in an ice bath. The solution should be clear and have a low viscosity at this stage.

- Induction of Self-Assembly:

- Salt-Triggered Assembly: Add a calculated volume of a sterile, concentrated phosphate-buffered saline (PBS) or Dulbecco's PBS (DPBS) solution to the aqueous PA solution to achieve physiological ionic strength (e.g., 1x PBS). Mix gently. An immediate increase in viscosity and gelation will be observed.

- pH-Triggered Assembly: Alternatively, for PAs containing acidic residues, self-assembly can be initiated by adding a minimal volume of a basic solution (e.g., NaOH) to neutralize the charges and reduce electrostatic repulsion.

- Ionic Crosslinking: To enhance the mechanical stability of the hydrogel, the PA nanofiber network can be ionically crosslinked. This is achieved by the addition of divalent cations such as Ca²⁺ or Mg²⁺ (e.g., from CaCl₂ solution), which chelate with terminal carboxylic acid groups on the PA fibers [5].

Protocol: In Vitro Angiogenesis Assay

This protocol assesses the pro-angiogenic potential of the bioactive PA nanofibers by measuring their ability to promote endothelial tube formation, a critical process in wound healing [5].

- Preparation of Gelled PA Substrate:

- Place a 24-well culture plate on ice. Add 300 µL of the sterile aqueous PA solution (prepared in Protocol 4.2, Step 1) to each well.

- Carefully add 300 µL of sterile, warm (37°C) cell culture medium (e.g., EGM-2 for HUVECs) containing 2x concentration of serum and ions to trigger gelation. Gently swirl to mix without introducing bubbles.

- Incubate the plate at 37°C for 30 minutes to allow a firm gel to form.

- Cell Seeding and Tubule Formation:

- Trypsinize and harvest human umbilical vein endothelial cells (HUVECs). Resuspend the cells in complete endothelial cell growth medium.

- Seed HUVECs onto the surface of the pre-formed PA gel at a density of 1.0 x 10⁵ cells per well.

- Incubate the cells at 37°C, 5% CO₂ for 6-18 hours.

- Imaging and Quantification:

- After incubation, image the tubular structures using an inverted phase-contrast microscope at 4x or 10x magnification. Acquire multiple non-overlapping images per well.

- Analyze the images using image analysis software (e.g., ImageJ with the Angiogenesis Analyzer plugin). Quantify key parameters including the total tube length, number of branches, and number of master segments per field of view. Compare results to control groups (e.g., cells on non-bioactive PA gels or tissue culture plastic).

The Scientist's Toolkit: Essential Research Reagents

Successful research and development in supramolecular biomaterials require a specific set of reagents and instruments. The following table lists the essential components for working with peptide amphiphile nanofibers.

Table 3: Essential Research Reagents and Materials for PA Nanofiber Development

| Item Category | Specific Examples | Function/Purpose |

|---|---|---|

| Synthesis & Purification | Rink Amide Resin, Fmoc-Protected Amino Acids, Palmitic Acid, HBTU/HOBt, DIPEA, Trifluoroacetic Acid (TFA), HPLC-grade solvents (Acetonitrile, Water) | Solid-phase synthesis of the PA molecule; cleavage from resin; purification and analysis of the final product [5] [8]. |

| Assembly & Formulation | Ultrapure Water, Phosphate-Buffered Saline (PBS), Calcium Chloride (CaCl₂) Solution | To solubilize PA monomers; trigger self-assembly into nanofibers via physiological electrolytes; and ionically crosslink the nanofiber network to form a hydrogel [3] [5]. |

| Characterization | Liquid Chromatography-Mass Spectrometry (LC-MS), Circular Dichroism (CD) Spectropolarimeter, Transmission Electron Microscope (TEM), Rheometer | Confirm PA identity and purity; analyze secondary structure (β-sheet content); visualize nanofiber morphology; and measure mechanical properties of the hydrogel [5]. |

| Biological Assessment | Human Dermal Fibroblasts (hFBs), Human Umbilical Vein Endothelial Cells (HUVECs), Cell Culture Media and Supplements, Lactate Dehydrogenase (LDH) Assay Kit, Matrigel (for assay control) | Evaluate biocompatibility (cytotoxicity); assess functional bioactivity, such as the ability to promote angiogenesis in vitro [7] [5]. |

Application Workflow for a Sprayable Wound Dressing

The pathway from molecular design to functional application integrates synthesis, characterization, and formulation steps. The following diagram outlines the comprehensive workflow for developing a sprayable PA nanofiber dressing, highlighting the key decision points and quality control checks.

The native extracellular matrix (ECM) is a dynamic, three-dimensional network of proteins and polysaccharides that provides not only structural support but also critical biochemical and mechanical signals that direct cellular behavior. Mimicking this complex environment represents a frontier in developing advanced therapies for wound healing, particularly for chronic wounds that fail to progress through normal healing phases. The ECM's composition is tissue-specific and undergoes constant remodeling through covalent and non-covalent interactions, creating impressive functions ranging from cellular signaling to structural integrity maintenance [9]. In chronic wounds, several pathophysiological mechanisms impede healing, including excessive ECM degradation by proteases, poor vascularization, decreased growth factor activity, and bacterial infection [4]. By creating biomaterials that replicate key aspects of the native ECM—architectural, mechanical, and bioactive properties—researchers can develop more effective wound treatments that actively promote regeneration rather than merely providing a passive covering.

The emergence of supramolecular biomaterials, particularly peptide-based systems that self-assemble into nanostructured environments, has created unprecedented opportunities for ECM mimicry. These materials can be designed "from scratch" with tunable properties, allowing precise control over their interaction with cellular components [9] [4]. When formulated as sprayable hydrogels incorporating peptide amphiphiles, these ECM-mimetic materials offer additional advantages for wound care, including conformal application to irregular wound beds, minimally invasive delivery, and the potential for in situ polymerization that enables on-demand gelation at target sites [10]. This application note details the principles, quantitative parameters, and experimental protocols for leveraging these advanced biomaterial platforms in wound healing research.

Quantitative Landscape of ECM-Mimetic Biomaterials

The design of biomaterials that mimic the native ECM requires careful consideration of architectural, mechanical, and biological parameters. The following tables summarize key quantitative data for major biomaterial classes used in ECM mimicry for wound healing applications.

Table 1: Architectural and Mechanical Properties of ECM-Mimetic Biomaterials

| Biomaterial Class | Fiber Diameter/Structure | Elastic Modulus/Stiffness | Porosity | Degradation Profile |

|---|---|---|---|---|

| Electrospun Nanofibers (Polysaccharide-based) [11] | 50-500 nm (mimicking natural ECM fibers) | Varies with polymer blend (e.g., Sol/SPI/Mp: 3.61 ± 0.29 MPa tensile strength) | High porosity (>80% reported for Sol/SPI systems) | Sol/SPI/Mp: 33.73 ± 3.55% degradation in 5 days in vitro |

| Peptide Amphiphile (PA) Nanofibers [12] [4] | 5-10 nm diameter, μm length (β-sheet nanofibers) | Tunable via peptide sequence; RGDS-PA gels showed significant healing enhancement | Nanofibrous hydrogel with high water content | Proteolytically degradable; sequence-dependent rates |

| Self-Assembled Peptides (SAPs) [4] | β-sheet nanofibers (e.g., RADA16-I: ~10 nm) | Tunable mechanics via concentration (e.g., FF hydrogels) | Nanoscale mesh with hydrogel properties | Susceptible to protease degradation; can be crosslinked |

| Supramolecular Hydrogels [9] | Hierarchical structures from self-assembly | Viscoelastic; can mimic tissue-specific mechanics (1.9 kPa lungs to 20 GPa bone) | Hydrated network permeable to nutrients/cells | Dynamic/reversible bonds enable remodeling |

Table 2: Functional Performance Metrics of ECM-Mimetic Wound Dressings

| Biomaterial System | Antimicrobial Efficacy | Wound Closure Rate | Cellular Response | Key Bioactive Components |

|---|---|---|---|---|

| AMP-Loaded Dressings [13] | Broad-spectrum activity; anti-biofilm properties | Enhanced re-epithelialization in chronic wounds | Stimulates cell proliferation, angiogenesis, immunomodulation | Antimicrobial peptides (e.g., LL-37, defensins) |

| Sol/SPI/Mp Nanofibers [14] | 93.06% S. aureus, 90.40% E. coli kill rate | Fastest re-epithelialization in rat model | Notable HaCat keratinocyte biocompatibility | Mupirocin, soy protein isolate, Soluplus |

| RGDS-PA Nanofiber Gels [12] | Not specifically reported | Significantly enhanced re-epithelialization days 7-28 in burns | Increased proliferation of thermally damaged fibroblasts and HUVECs | RGDS (Arg-Gly-Asp-Ser) peptide sequence |

| Chitosan-based Nanofibers [11] | Broad antibacterial (S. aureus, E. coli) via NH3+ interaction | Accelerated wound healing in various models | Promotes cell adhesion and proliferation | Chitosan (cationic polysaccharide) |

Experimental Protocols for ECM-Mimetic Biomaterial Evaluation

Protocol: Fabrication of Electrospun Nanofibrous Dressings

Principle: Electrospinning uses high-voltage electric fields to produce continuous polymer nanofibers that architecturally mimic the native ECM, creating high surface area-to-volume ratio scaffolds ideal for cell adhesion and bioactive factor delivery [11] [14].

Materials:

- Polymer solution (e.g., Soluplus, soy protein isolate, peptide amphiphiles)

- High-voltage power supply (0-30 kV capability)

- Syringe pump with flow rate control

- Collector plate (stationary or rotating)

- Solvent system appropriate for polymers

Procedure:

- Prepare polymer solution at optimal concentration (e.g., 33% w/v Soluplus in distilled water, 10% w/v SPI) with stirring for homogeneous dissolution [14].

- For drug-loaded systems, incorporate bioactive agents (e.g., 2% w/w mupirocin) into polymer solution with continuous stirring.

- Load solution into syringe with metallic needle (0.6 mm diameter typical).

- Set syringe pump to controlled flow rate (e.g., 1 mL/h).

- Apply high voltage (e.g., 15 kV) between needle and collector.

- Maintain fixed distance (e.g., 12 cm) between needle and collector.

- Collect nanofibers on aluminum foil or other substrate.

- Characterize fiber morphology by SEM, diameter distribution by ImageJ analysis.

Technical Notes:

- Solution parameters (viscosity, conductivity, surface tension) critically influence fiber morphology [11].

- Environmental parameters (temperature, humidity) must be controlled for reproducibility.

- Coaxial electrospinning can be employed for core-shell structures protecting bioactive components [11].

Protocol: Functional Characterization of Wound Dressings

Principle: Comprehensive evaluation of physical, mechanical, and biological properties predicts in vivo performance and ensures biomaterials meet requirements for wound healing applications [14].

Mechanical Testing:

- Cut nanofiber mats into standardized specimens (e.g., 10×50 mm strips).

- Perform tensile testing using universal testing machine.

- Calculate ultimate tensile strength, elastic modulus, and elongation at break from stress-strain curves.

Water Absorption and Permeability:

- Weigh dry nanofiber samples (20×20 mm).

- Immerse in distilled water for 24 hours.

- Remove, blot excess surface water, and reweigh.

- Calculate water absorption percentage: [(Wwet - Wdry)/Wdry] × 100.

- For water vapor permeability, use gravimetric method: measure weight loss of water-filled cup covered with nanofiber membrane over 24 hours.

In Vitro Degradation:

- Weigh initial dry samples (Winitial).

- Immerse in phosphate-buffered saline (PBS) or simulated wound fluid at 37°C.

- At predetermined time points, remove samples, dry completely, and reweigh (Wfinal).

- Calculate degradation percentage: [(Winitial - Wfinal)/Winitial] × 100.

Antibacterial Assessment:

- Prepare bacterial suspensions (S. aureus, E. coli) at ~10⁶ CFU/mL in nutrient broth.

- Incubate with nanofiber samples for 24 hours at 37°C.

- Plate serial dilutions on agar plates.

- Count colonies after 24 hours incubation.

- Calculate bacterial reduction percentage compared to control.

Protocol: In Vivo Evaluation of Wound Healing Efficacy

Principle: Animal models provide critical assessment of biomaterial performance in complex biological environments, measuring re-epithelialization, tissue regeneration, and immune response [12] [14].

Materials:

- Animal model (e.g., rat, mouse)

- Burn/wound creation apparatus

- Test biomaterials (nanofiber dressings, hydrogels)

- Histological supplies (fixatives, stains, embedding materials)

Procedure:

- Anesthetize animals according to approved protocol.

- Create standardized wounds (e.g., deep partial-thickness burns, excisional wounds).

- Apply test biomaterials to wound beds.

- Use appropriate controls (no treatment, commercial dressings).

- Monitor wound closure through regular imaging and planimetric analysis.

- Harvest tissue samples at predetermined endpoints (e.g., days 7, 14, 21, 28).

- Process samples for histology (H&E staining, Masson's trichrome for collagen).

- Evaluate re-epithelialization, granulation tissue formation, collagen deposition, and immune cell infiltration.

Technical Notes:

- RGDS-PA nanofiber gels showed significant enhancement of re-epithelialization between days 7-28 in burn wounds [12].

- Sol/SPI/Mp nanofibers demonstrated the fastest re-epithelialization and wound healing in rat models [14].

- Chronic wound models (diabetic, ischemic) provide more clinically relevant assessment for pathological healing impairment.

Signaling Pathways in ECM-Biomaterial Interactions

The interaction between cells and ECM-mimetic biomaterials occurs through specific receptor-mediated signaling pathways that direct cellular responses critical for wound healing. The integrin receptor family serves as a primary mediator of cell-biomaterial interactions, initiating signaling cascades that influence cell adhesion, migration, proliferation, and differentiation [9].

Diagram Title: ECM-Biomaterial Signaling in Wound Healing

The diagram illustrates how ECM-mimetic biomaterials, particularly those containing bioactive motifs like RGDS, activate integrin receptors that trigger intracellular signaling cascades through focal adhesion kinase (FAK). This initiation leads to two primary pathways: the Ras-MAPK pathway driving cell proliferation, and the PI3K-Akt pathway promoting cell survival and angiogenesis. Concurrently, integrin activation facilitates cytoskeleton reorganization, enabling cell migration critical for re-epithelialization. These coordinated cellular responses collectively contribute to enhanced wound healing outcomes observed with peptide amphiphile nanofibers and other ECM-mimetic biomaterials [12] [9].

Self-Assembly Mechanisms of Peptide-Based Biomaterials

Peptide amphiphiles and self-assembling peptides form nanostructured biomaterials through well-defined molecular mechanisms that create ECM-mimetic architectures. Understanding these assembly pathways is essential for rational design of sprayable wound healing formulations.

Diagram Title: Peptide Amphiphile Self-Assembly Pathway

The self-assembly process begins with peptide amphiphile monomers containing four distinct domains: a bioactive domain for receptor binding, a polar domain for aqueous solubility, a stabilization domain (typically β-sheet forming), and a hydrophobic tail. Upon environmental triggers such as pH change, salt concentration, or temperature adjustment, these monomers undergo molecular self-assembly through non-covalent interactions including hydrogen bonding, van der Waals forces, hydrophobic interactions, and π-π stacking. This process yields cylindrical β-sheet nanofibers with diameters of 5-10 nm, which subsequently entangle to form nanofibrous hydrogels with viscoelastic properties, topography, and bioactive signaling reminiscent of native ECM [4]. The resulting three-dimensional structure is easily tunable by modifying the amino acid sequence, allowing precise control over mechanical and biological properties for specific wound healing applications.

Research Reagent Solutions for ECM-Mimetic Wound Healing Studies

Table 3: Essential Research Reagents for ECM-Mimetic Biomaterial Development

| Reagent/Category | Function/Application | Representative Examples | Key Characteristics |

|---|---|---|---|

| Peptide Amphiphiles (PAs) | Self-assembling nanofiber formation | RGDS-PA, RADA16-I, RADA16-II, EAK16-II | Four-domain structure: bioactive, polar, stabilization, hydrophobic; β-sheet formation [12] [4] |

| Structural Polymers | Electrospinning matrix materials | Chitosan, Soluplus, Soy Protein Isolate (SPI), Polyvinyl alcohol (PVA) | Biocompatibility, tunable mechanics, processing versatility [11] [14] |

| Antimicrobial Agents | Infection control in wound dressings | Mupirocin, antimicrobial peptides (LL-37, defensins) | Broad-spectrum activity, low resistance propensity, biofilm disruption [13] [14] |

| Bioactive Motifs | Cellular recognition and signaling | RGDS (Arg-Gly-Asp-Ser), IKVAV, YIGSR | Integrin-binding domains, promotion of cell adhesion and migration [12] [9] |

| Crosslinking Agents | Modifying mechanical stability and degradation | Physical (temperature, pH), chemical (genipin, glutaraldehyde) | Control of structural integrity, tunable degradation rates [10] |

| Characterization Tools | Material property assessment | SEM, FTIR, tensile testing, BET surface area analysis | Verification of nanostructure, chemistry, mechanics, porosity [14] |

The research reagents outlined in Table 3 represent core components for developing and evaluating ECM-mimetic biomaterials for wound healing. Peptide amphiphiles serve as fundamental building blocks for self-assembling systems, with RGDS-modified PAs demonstrating significant enhancement of re-epithelialization in burn wound models [12]. Structural polymers like chitosan and Soluplus/SPI blends provide the macromolecular framework for electrospun nanofibers, offering both processability and bioactivity. Antimicrobial agents address the critical concern of infection in chronic wounds, with AMP-loaded dressings providing broad-spectrum activity and anti-biofilm properties while mitigating resistance development [13]. Incorporating bioactive motifs such as RGDS enables specific integrin-mediated cellular interactions that direct healing processes, while crosslinking agents allow fine-tuning of mechanical properties and degradation kinetics to match specific wound requirements. Comprehensive characterization using the outlined tools ensures reproducible fabrication and predictable in vivo performance.

The design of advanced biomaterials for wound healing is increasingly focused on mimicking the native extracellular matrix (ECM) to direct specific cellular responses. Within this framework, short bioactive peptide sequences derived from full-length ECM proteins have emerged as powerful tools for functionalizing synthetic materials. The RGDS (Arg-Gly-Asp-Ser) and IKVAV (Ile-Lys-Val-Ala-Val) epitopes are two of the most prominent and well-studied sequences, each playing a unique and critical role in cellular signaling, adhesion, and differentiation [15] [16]. Their integration into sprayable peptide amphiphile nanofiber systems presents a promising strategy for creating proactive wound dressings that not only provide a scaffold but also actively instruct the local cellular environment to promote healing. This application note details the molecular mechanisms, quantitative bioactivity, and experimental protocols for utilizing these epitopes in wound healing research.

Molecular Mechanisms and Signaling Pathways

RGDS: The Master Integrin Binder

The RGDS sequence is a canonical recognition motif found in numerous ECM proteins, including fibronectin, vitronectin, and fibrinogen [17] [18]. Its primary function is to serve as a ligand for the integrin family of cell surface receptors.

- Integin Binding: RGDS binds to a subset of integrins, including α5β1, αvβ3, and αIIbβ3 [17] [19]. This interaction is a cornerstone of cell-ECM adhesion.

- Outside-In Signaling: Ligand binding induces integrin clustering and the formation of focal adhesion complexes, initiating crucial downstream signaling pathways such as FAK (Focal Adhesion Kinase) and Src kinase activation [17]. This signaling cascades to influence cell survival, proliferation, and migration—all vital processes in wound healing.

- Role in Healing: In the context of wounds, RGDS promotes the attachment and spreading of fibroblasts and keratinocytes, facilitates angiogenesis by supporting endothelial cell function, and enhances the deposition of new ECM [15] [19].

The following diagram illustrates the key signaling pathway triggered by RGDS-integrin interaction:

IKVAV: A Multifunctional Laminin Epitope

The IKVAV sequence is derived from the α1-chain of laminin-1, a major component of the basement membrane [16]. Its bioactivity extends beyond simple adhesion to encompass potent modulation of cell behavior.

- Integrin Interaction: IKVAV is known to interact with integrin receptors, with recent research pointing to a role for α2β1 integrin in mediating its effects on certain cell types, including macrophages [16].

- Cellular Differentiation: A key function of IKVAV is the promotion of neurite outgrowth and the differentiation of neural stem/progenitor cells [20]. This makes it highly relevant for nerve regeneration within wound beds.

- Immunomodulation: Emerging evidence indicates that IKVAV can modulate macrophage phenotype, reducing pro-inflammatory (M1) markers and promoting anti-inflammatory (M2) markers, thereby potentially resolving chronic inflammation [16].

- Angiogenic Potential: IKVAV also exhibits pro-angiogenic abilities, supporting the formation of new blood vessels [16] [20].

The multifaceted cellular responses to the IKVAV peptide are summarized below:

Quantitative Bioactivity and Performance Data

The efficacy of RGDS and IKVAV is concentration-dependent and influenced by their presentation format. The data below summarizes key quantitative findings from recent literature.

Table 1: Quantitative Bioactivity Profile of RGDS and IKVAV Peptides

| Peptide Epitope | Cellular Assay / Model | Key Quantitative Outcome | Optimal Concentration / Density | Reference |

|---|---|---|---|---|

| RGDS | Mesenchymal stem cell adhesion on hydroxyapatite | Enhanced initial cell attachment; higher densities can inhibit bone formation in vivo when competing with adsorbed serum proteins. | Controlled density is critical; low densities enhance attachment. | [21] |

| RGDS | Fibroblast and keratinocyte adhesion in wound matrices | Promotes attachment, spreading, and proliferation of skin cells crucial for re-epithelialization. | Varies by material system; often used in 0.1-2.0 mM range for functionalization. | [15] [19] |

| IKVAV | Murine macrophage (M1) culture in 2D | Reduced iNOS expression from 82.13 ± 23.97 a.u. to 50.95 ± 7.3 a.u.; increased Arg-1 expression in M0 macrophages. | 3 mM (soluble treatment). | [16] |

| IKVAV | Neurogenic PC-12 cell culture | Concentration-dependent effects on proliferation and morphological differentiation. | Existence of an optimal-density range for peptide incorporation. | [20] |

| Cyclic RGD | Glioma-targeted drug delivery | Demonstrated ~1000x greater binding affinity for αvβ3 integrin compared to linear RGD. | N/A (affinity comparison). | [19] |

Experimental Protocols

Protocol 1: Functionalization of Biomaterials with RGDS and IKVAV

This protocol describes a method for covalently incorporating peptide epitopes into a gelatin-based cryogel or hydrogel, adaptable for sprayable nanofiber systems.

- Principle: Peptides are modified with terminal functional groups (e.g., lysine residues) to enable in-situ cross-linking during polymer network formation [20].

- Materials:

- Synthetic Peptides: K-RGDS-K and K-IKVAV-K (with N- and C-terminal lysines).

- Polymer Matrix: Gelatin methacryloyl (GelMA) or other cross-linkable biopolymer.

- Cross-linker: Glutaraldehyde or a photo-initiator (e.g., Irgacure 2959 for UV cross-linking).

- Procedure:

- Peptide Synthesis: Synthesize and purify K-RGDS-K and K-IKVAV-K peptides using standard Fmoc solid-phase peptide synthesis. Confirm structure via HPLC and mass spectrometry [20].

- Precursor Solution Preparation: Dissolve the GelMA polymer (e.g., 5-10% w/v) in PBS. Separately, dissolve the modified peptides in PBS.

- Mixing and Cross-linking: Combine the GelMA solution with the peptide solution at the desired molar ratio. Add cross-linker (e.g., 0.25% v/v glutaraldehyde for chemical cross-linking) or photo-initiator (0.5% w/v for UV cross-linking). Mix thoroughly.

- Cryogel Formation (Optional): For cryogels, pour the mixture into a mold and freeze at -16°C for 16 hours, then thaw at room temperature [20].

- Hydrogel Formation: For hydrogels, expose the mixture to UV light (e.g., 365 nm, 5-10 mW/cm² for 2-5 minutes) to initiate cross-linking.

- Washing: Wash the resulting functionalized gel extensively in sterile PBS or deionized water to remove unreacted species.

Protocol 2: In Vitro Assessment of Macrophage Immunomodulation

This protocol is used to evaluate the effect of IKVAV on macrophage polarization, a key process in regulating wound inflammation.

- Principle: Soluble IKVAV peptide is applied to macrophages stimulated towards a pro-inflammatory (M1) phenotype, and changes in phenotypic markers are quantified [16].

- Materials:

- Cells: Murine macrophage cell line (e.g., RAW 264.7) or primary bone marrow-derived macrophages.

- IKVAV Peptide: Soluble IKVAV peptide stock solution (e.g., 30 mM in PBS).

- Inducers: Lipopolysaccharide (LPS, 100 ng/mL) and Interferon-gamma (IFN-γ, 20 ng/mL) for M1 polarization.

- Procedure:

- Cell Seeding: Seed macrophages in 24-well plates at a density of 2 x 10^5 cells per well and allow to adhere overnight.

- Treatment: Pre-treat cells with 3 mM IKVAV peptide for 1 hour.

- Polarization: Stimulate macrophages with LPS/IFN-γ in the continued presence of IKVAV for 18-24 hours to induce M1 polarization.

- Analysis:

- Immunocytochemistry: Fix cells and stain for M1 marker (iNOS) and M2 marker (Arg-1). Quantify mean fluorescence intensity.

- Gene Expression: Extract RNA, perform reverse transcription, and analyze expression of pro-inflammatory (e.g., TNF-α, IL-6) and anti-inflammatory (e.g., IL-10, Arg-1) genes via qPCR [16].

The workflow for this immunomodulation assay is outlined below:

Integration into Sprayable Peptide Amphiphile Nanofibers

For wound healing applications, the RGDS and IKVAV epitopes can be engineered into the design of peptide amphiphile (PA) molecules. These PAs self-assemble in physiological conditions to form nanofibers that display a high density of bioactive signals at the surface.

- Molecular Design: The PA molecule typically includes a hydrophobic tail, a β-sheet forming sequence, and the bioactive epitope (RGDS or IKVAV) at the N-terminus.

- Sprayable Formulation: The PAs can be formulated as a solution in a sterile, biocompatible buffer (e.g., PBS or sucrose solution). Upon spray application to the wound bed, which often involves a change in ionic strength or pH, the PAs spontaneously self-assemble into a nanofiber network that forms a hydrogel in situ, creating a protective, bioactive barrier [15] [22].

- Functional Synergy: A co-assembling system containing both RGDS-PA and IKVAV-PA can be created. This allows for a single sprayable dressing that simultaneously promotes cell adhesion and migration (via RGDS) while modulating inflammation and encouraging neurite ingrowth (via IKVAV), addressing multiple aspects of the healing process concurrently.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents for Working with RGDS and IKVAV Epitopes

| Reagent / Material | Function and Application | Example Use Case |

|---|---|---|

| Linear RGDS Peptide | Promotes general cell adhesion and spreading via integrin binding. Functionalization of 2D surfaces for cell culture or simple hydrogel systems. | Studying fibroblast migration in a 2D wound healing assay. |

| Cyclic RGDfK Peptide | Offers superior stability and binding affinity to αvβ3 integrin; used for targeted delivery and potent angiogenesis inhibition. | Targeting therapeutic nanoparticles to angiogenic endothelial cells in wounds. |

| K-IKVAV-K Peptide | Modified peptide with terminal lysines for efficient covalent cross-linking into polymer matrices during fabrication. | Creating stable, IKVAV-functionalized cryogels for neural tissue engineering [20]. |

| Gelatin Methacryloyl (GelMA) | A photocrosslinkable, tunable hydrogel backbone that mimics the natural ECM. | Forming sprayable, UV-curable hydrogels for wound dressing. |

| Poly-ε-Caprolactone (PCL) | A biodegradable synthetic polymer providing mechanical strength; often used as a conduit or shell. | Fabricating a supportive outer tube for a nerve guidance conduit [20]. |

| Irgacure 2959 | A cytocompatible photo-initiator for UV-induced cross-linking of hydrogels. | Cross-linking GelMA-based sprayable formulations upon application to a wound. |

The clinical management of chronic wounds, such as diabetic foot ulcers and venous leg ulcers, presents a substantial global healthcare challenge, with an estimated prevalence of between 1.47 and 2.2 per 1,000 population [10]. For researchers developing advanced therapeutic solutions like sprayable peptide amphiphile (PA) nanofibers, two fundamental properties dictate translational success: biocompatibility and biodegradability. These inherent characteristics ensure that a biomaterial can perform its function without eliciting adverse host responses while harmoniously supporting the body's natural healing processes.

Peptide amphiphiles are a class of molecules specifically engineered to address these requirements. Their typical molecular architecture includes: (1) a hydrophobic alkyl tail, (2) a β-sheet forming peptide sequence that promotes self-assembly, (3) charged amino acids for solubility, and (4) a bioactive peptide epitope at the terminus for cell signaling [3]. This precise molecular design enables PAs to spontaneously assemble in physiological conditions into supramolecular nanofibers that closely mimic the native extracellular matrix (ECM) [23] [24], creating a bioactive scaffold ideal for wound healing applications.

This document provides detailed application notes and standardized protocols to assist researchers in quantifying, validating, and applying these critical properties in the development of PA-based wound healing technologies.

Molecular Design Rationale for Biocompatibility and Biodegradability

The inherent biocompatibility of PAs stems from their peptide-based composition. As these molecules are constructed from natural amino acids, they present a familiar biochemical interface to cells, promoting favorable cellular interactions while minimizing cytotoxicity and inflammatory responses [23]. The presentation of bioactive signals, such as the RGDS (Arg-Gly-Asp-Ser) epitope derived from fibronectin, further enhances biocompatibility by promoting specific integrin-mediated cell adhesion—a crucial process during wound healing [3].

Biodegradability is engineered into PA molecules through the incorporation of peptide bonds susceptible to hydrolysis or enzymatic cleavage by proteases present in the wound environment [23]. This ensures that the nanofibrous scaffold undergoes controlled resorption, gradually making way for newly formed natural tissue without requiring surgical removal. The degradation rate can be tuned by modifying the peptide sequence, with more labile amino acid sequences resulting in faster breakdown [24].

Table 1: Key Molecular Components of Peptide Amphiphiles and Their Functional Roles

| Molecular Component | Chemical Features | Primary Function | Impact on Biocompatibility/Biodegradability |

|---|---|---|---|

| Hydrophobic Tail | Alkyl chain (e.g., palmitic acid) | Drives self-assembly via hydrophobic collapse; forms core of nanofiber [3] | Affects interaction with cell membranes; longer chains can slow degradation [25] |

| β-Sheet Forming Sequence | Short peptide (e.g., VVVAAA) | Enables hydrogen bonding; dictates one-dimensional nanofiber growth [3] [23] | Stable yet dynamic structure; bonds are susceptible to enzymatic cleavage [23] |

| Charged Amino Acids | Ionizable residues (e.g., glutamic acid, lysine) | Provides aqueous solubility; enables salt-responsive gelation [3] | Electrostatic interactions can influence protein adsorption and cell behavior [23] |

| Bioactive Epitope | Short signaling sequence (e.g., RGDS, IKVAV) | Confers specific bioactivity (e.g., cell adhesion, differentiation) [3] | Directly mediates cell-scaffold communication, crucial for biocompatibility [3] [23] |

Diagram 1: PA Design Principles for Wound Healing

Quantitative Assessment of Material Properties

Rigorous in vitro characterization is essential to validate the performance of PA nanofibers before proceeding to complex animal models or clinical studies. The following tables summarize key parameters and methods for evaluating the core properties of PA-based hydrogels and nanofibers.

Table 2: Key Parameters for Assessing Biocompatibility of PA Nanofibers

| Assessment Method | Measured Parameters | Typical Target/Outcome for PAs | Relevant Standard |

|---|---|---|---|

| MTT/XTT Assay | Cell viability (%) , Metabolic activity | >90% viability relative to control [26] [14] | ISO 10993-5 |

| Live/Dead Staining | Ratio of live to dead cells, Cell morphology | High density of live cells, normal morphology | ISO 10993-5 |

| Hemolysis Assay | Hemoglobin release (%) | <5% hemolysis [14] | ASTM F756 |

| Cytokine ELISA | Inflammatory cytokine levels (e.g., TNF-α, IL-6) | Significant reduction vs. negative control | N/A |

| Direct Contact Assay | Cell morphology, Lysis, Growth inhibition | Grade 0 (no reactivity) or Grade 1 (slight reactivity) | ISO 10993-5 |

Table 3: Key Parameters for Assessing Biodegradability of PA Nanofibers

| Assessment Method | Measured Parameters | Degradation Influencing Factors | Data Interpretation |

|---|---|---|---|

| Mass Loss Measurement | Remaining mass (%) over time | Peptide sequence, Crosslinking density, Protease concentration | Degradation profile should match tissue ingrowth rate [23] |

| Gel Permeation Chromatography (GPC) | Molecular weight change, Dispersity | Cleavage of peptide bonds, Fragment solubility | Shift to lower molecular weights indicates breakdown |

| Rheology | Storage (G') and Loss (G'') moduli | Network integrity, Fiber disassembly | Drop in G' indicates loss of mechanical structure |

| HPLC/MS Analysis | Degradation product identification | Enzyme specificity, Environmental pH | Identifies non-toxic degradation products (amino acids) [23] |

| Scanning Electron Microscopy (SEM) | Nanofiber morphology, Pore size, Surface erosion | Self-assembly stability, Solubility of segments | Visual confirmation of structural disintegration |

Experimental Protocols

Protocol: Synthesis and Purification of Peptide Amphiphiles

This protocol describes the solid-phase peptide synthesis (SPPS) of a model PA, C16-VVVAAAGGRGDS, incorporating a hydrophobic tail, a β-sheet domain, and a bioactive RGDS sequence [3] [26].

Research Reagent Solutions:

- Resin: Rink Amide resin (loading: 0.5 mmol/g)

- Amino Acids: Fmoc-protected amino acids: Fmoc-Ser(tBu)-OH, Fmoc-Asp(OtBu)-OH, Fmoc-Gly-OH, Fmoc-Arg(Pbf)-OH, Fmoc-Ala-OH, Fmoc-Val-OH

- Solvents: Dimethylformamide (DMF), Dichloromethane (DCM), Diethyl ether

- Reagents for Coupling: 2-(1H-Benzotriazol-1-yl)-1,1,3,3-tetramethyluronium hexafluorophosphate (HBTU), N,N-Diisopropylethylamine (DIEA)

- Deprotection Reagent: 20% (v/v) Piperidine in DMF

- Cleavage Cocktail: 95:2.5:2.5 Trifluoroacetic Acid (TFA) : Triisopropylsilane : Water

- Lipid Conjugation: Palmitic acid

Methodology:

Resin Preparation: Place 1.0 g of Rink Amide resin (0.5 mmol) into a solid-phase reaction vessel. Swell the resin in 10 mL DCM for 30 minutes, then drain. Perform Fmoc deprotection by treating the resin with 10 mL of 20% piperidine/DMF solution for 2 x 10 minutes with gentle agitation. Drain and wash the resin thoroughly with DMF (5 x 10 mL).

Peptide Chain Elongation:

- For each amino acid in the sequence (from C-terminal to N-terminal, starting with Ser), perform the following coupling cycle:

- Coupling: Prepare a solution of 4 equivalents of the Fmoc-amino acid, 3.95 equivalents of HBTU, and 6 equivalents of DIEA in 10 mL DMF. Add this solution to the resin and agitate for 45-60 minutes. Drain and wash with DMF (3 x 5 mL).

- Deprotection: Add 10 mL of 20% piperidine/DMF to remove the Fmoc group, agitate for 2 x 10 minutes. Drain and wash with DMF (3 x 5 mL).

- Monitor coupling completion using the Kaiser test.

- After coupling the final N-terminal amino acid (Val), conjugate palmitic acid using the same coupling protocol.

Cleavage and Deprotection: Drain the resin and wash sequentially with DMF, DCM, and methanol. Transfer the resin to a clean vessel and add 10 mL of the TFA-based cleavage cocktail. Agitate the mixture for 3 hours at room temperature. Filter the solution to separate the cleaved peptide from the resin, collecting the filtrate.

Precipitation and Purification: Precipitate the crude PA by slowly adding the TFA filtrate into 50 mL of cold diethyl ether in a centrifuge tube. Centrifuge at 4000 rpm for 10 minutes at 4°C to pellet the product. Decant the supernatant and wash the pellet with fresh cold ether. Repeat the centrifugation and washing steps twice.

- Dissolve the crude pellet in water and lyophilize to obtain a white powder.

- Purify the PA using reversed-phase High-Performance Liquid Chromatography (HPLC). Confirm the molecular weight and purity using Mass Spectrometry (MS) and analytical HPLC [26].

Diagram 2: PA Synthesis Workflow

Protocol: In Vitro Biocompatibility and Cytotoxicity Assessment (MTT Assay)

This protocol assesses the cytotoxicity of PA nanofiber degradation products on human dermal fibroblasts (HDFs) according to ISO 10993-5 standards [26] [14].

Research Reagent Solutions:

- Cells: Human Dermal Fibroblasts (HDFs)

- Culture Medium: Dulbecco's Modified Eagle Medium (DMEM) supplemented with 10% Fetal Bovine Serum (FBS) and 1% Penicillin-Streptomycin.

- Test Material: PA nanofibers (sterilized under UV light for 30 minutes).

- Extraction Medium: Serum-free DMEM.

- MTT Reagent: 3-(4,5-Dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide, prepared as 5 mg/mL stock in PBS.

- Solubilization Solution: Dimethyl Sulfoxide (DMSO).

Methodology:

Preparation of Extracts:

- Sterilize 100 mg of PA nanofibers and place them in 5 mL of extraction medium (resulting in a 20 mg/mL concentration).

- Incubate the mixture at 37°C for 24 hours under gentle agitation.

- After incubation, centrifuge the solution at 10,000 rpm for 10 minutes and collect the supernatant (the extract). Prepare serial dilutions of this extract in complete culture medium (e.g., 10 mg/mL, 5 mg/mL, 1 mg/mL).

Cell Seeding and Treatment:

- Harvest HDFs and seed them in a 96-well plate at a density of 1 x 10⁴ cells per well in 100 μL of complete medium.

- Incubate the plate for 24 hours at 37°C in a 5% CO₂ atmosphere to allow cell attachment.

- Carefully aspirate the medium from the wells and replace it with 100 μL of the various extract dilutions. Include control wells containing only complete medium (negative control) and wells with 1% Triton X-100 (positive control). Use at least 5 replicates per condition.

MTT Incubation and Measurement:

- After a 24-hour exposure period, carefully remove the treatment media.

- Add 100 μL of fresh serum-free medium containing 10% (v/v) of the MTT stock solution (final MTT concentration: 0.5 mg/mL) to each well.

- Incubate the plate for 4 hours at 37°C.

- Carefully remove the MTT solution and add 100 μL of DMSO to each well to dissolve the formed formazan crystals.

- Agitate the plate on an orbital shaker for 10 minutes to ensure complete dissolution.

- Measure the absorbance of each well at a wavelength of 570 nm, using a microplate reader.

Data Analysis:

- Calculate the percentage of cell viability for each test group using the formula:

Cell Viability (%) = (Mean Absorbance of Test Group / Mean Absorbance of Negative Control) x 100 - A material is generally considered non-cytotoxic if cell viability exceeds 90% relative to the negative control [26] [14].

- Calculate the percentage of cell viability for each test group using the formula:

Protocol: Enzymatic Biodegradation Profiling

This protocol monitors the mass loss of PA nanofiber hydrogels over time in the presence of collagenase, a protease relevant to the wound environment [23].

Research Reagent Solutions:

- Hydrogel Preparation: 1.0% (w/v) PA solution in PBS, gelled by adjusting pH or adding physiological salts.

- Enzyme Solution: Collagenase Type I, dissolved in PBS containing 1 mM CaCl₂, to a final activity of 50 U/mL.

- Control Buffer: PBS with 1 mM CaCl₂ (enzyme-free).

- Other: Phosphate Buffered Saline (PBS), Calcium Chloride (CaCl₂).

Methodology:

Hydrogel Preparation and Weighing:

- Prepare PA hydrogels in pre-weighed 1.5 mL microcentrifuge tubes (Wₜᵤᵦₑ). Allow the gels to set completely.

- Record the initial mass of the gel (Wᵢₙᵢₜᵢₐₗ) after removing any surface moisture.

Degradation Incubation:

- Carefully add 1.0 mL of the collagenase solution (50 U/mL) to the test gels. For control gels, add 1.0 mL of the control buffer.

- Incubate the tubes at 37°C under gentle agitation (50 rpm).

- Replace the enzyme solution and control buffer every 48 hours to maintain consistent enzyme activity.

Mass Loss Measurement:

- At predetermined time points (e.g., days 1, 3, 5, 7), carefully remove the incubation solution.

- Rinse the gels gently with distilled water to stop degradation and remove soluble degradation products.

- Blot the gels lightly with filter paper to remove excess surface water and record the wet mass (Wₜ).

- Lyophilize the gels until a constant dry mass is achieved (W𝒹).

Data Analysis:

- Calculate the percentage of remaining mass at each time point using both wet and dry mass measurements:

Remaining Mass (%) = (Wₜ / Wᵢₙᵢₜᵢₐₗ) x 100(for wet mass)Remaining Mass (%) = (W𝒹 / Wᵢₙᵢₜᵢₐₗ) x 100(for dry mass) - Plot the remaining mass (%) versus time to generate a degradation profile for the PA hydrogel. Compare the degradation rates between the enzyme-treated and control groups.

- Calculate the percentage of remaining mass at each time point using both wet and dry mass measurements:

The Scientist's Toolkit

Table 4: Essential Research Reagent Solutions for PA Wound Healing Studies

| Reagent / Material | Supplier Examples | Critical Function | Application Notes |

|---|---|---|---|

| Fmoc-Protected Amino Acids | NovaBiochem, Sigma-Aldrich | Building blocks for SPPS; R groups define PA bioactivity [27] [26] | Store desiccated at -20°C; quality critical for synthesis yield |

| Rink Amide Resin | NovaBiochem | Solid support for SPPS; yields C-terminal amide upon cleavage | Swell thoroughly in DCM before use for optimal coupling |

| HBTU / HATU | Sigma-Aldrich | Peptide coupling reagents; activate carboxyl group of amino acids | Freshly prepare in DMF immediately before use |

| Collagenase Type I | Worthington, Sigma-Aldrich | Models enzymatic degradation in the wound environment [23] | Activity varies by batch; prepare stock solutions fresh |

| Human Dermal Fibroblasts (HDFs) | ATCC | In vitro model for dermal layer; primary cells are preferred for relevance | Use low passage numbers (<8) for consistent, reliable data |

| MTT Reagent | Thermo Fisher, Sigma-Aldrich | Tetrazolium salt; measures mitochondrial activity in viability assays [14] | Filter sterilize stock solution; protect from light during storage |

Concluding Remarks

The strategic molecular design of peptide amphiphiles inherently provides the biocompatibility and biodegradability essential for effective wound healing scaffolds. The protocols outlined herein for synthesis, biocompatibility testing, and degradation profiling provide a foundational framework for researchers. Future developments in this field will likely focus on creating increasingly sophisticated "smart" PA systems that dynamically respond to specific wound microenvironment cues, such as pH or enzyme profiles, to further optimize the healing process for chronic wounds.

From Synthesis to Bedside: Fabricating and Delivering Sprayable Nanofiber Therapies

Peptide amphiphiles (PAs) represent a class of biomolecules gaining significant traction in advanced wound healing therapies. These molecules are synthetically designed to combine a hydrophobic segment, typically an alkyl tail, with a hydrophilic peptide sequence, enabling them to self-assemble in aqueous environments into supramolecular nanofibers [3]. These nanofibers are exceptionally valuable for regenerative medicine as they can closely mimic the structure and function of the native extracellular matrix (ECM)—a crucial factor in guiding cellular behavior during tissue repair [3] [28].

The relevance of PA nanofibers to wound healing is multifaceted. They can be functionalized with bioactive epitopes, such as the laminin-derived IKVAV sequence for neural outgrowth or the ubiquitous RGDS cell-adhesion motif, to directly influence cellular processes like migration, proliferation, and angiogenesis [3] [29]. Furthermore, the viscoelastic properties of PA assemblies can be engineered to be shear-thinning, meaning they can be easily sprayed onto complex wound geometries as a low-viscosity liquid, after which they rapidly reassemble into a stable, gel-like scaffold that covers the injury [5]. This sprayable delivery method is minimally invasive and conforms perfectly to irregular wound beds, making it an ideal platform for treating conditions like deep dermal burns and diabetic ulcers [5] [22]. The synthesis of these sophisticated molecules, therefore, forms the foundational step in creating next-generation wound dressings.

Solid-Phase Peptide Synthesis (SPPS) of Peptide Amphiphiles

Solid-Phase Peptide Synthesis is the most established and widely used method for the laboratory-scale production of peptide amphiphiles. Its principle advantage lies in its simplicity and high efficiency, allowing for the rapid, sequential addition of protected amino acids to a growing peptide chain that is covalently anchored to an insoluble solid support [5]. This facilitates the easy removal of excess reagents and by-products through simple filtration and washing steps, enabling high reaction yields.

Molecular Design of a Model Wound-Healing PA

A typical PA designed for a pro-angiogenic wound-healing application, as characterized in the search results, can be broken down into four key regions [3]:

- Hydrophobic Tail: A long alkyl chain (e.g., derived from palmitic acid) that drives self-assembly via hydrophobic collapse.

- β-Sheet Forming Region: A short peptide sequence (e.g., VVVAAA) with a high propensity for intermolecular hydrogen bonding, promoting one-dimensional nanofiber growth.

- Charged Segment: Amino acids with ionizable side chains (e.g., glutamic acid, E) that provide water solubility and allow for gelation triggered by physiological electrolytes.

- Bioactive Epitope: A terminal peptide signal (e.g., RGDS) that interacts with cell surface receptors to promote specific therapeutic outcomes such as cell adhesion and angiogenesis [5] [29].

Table 1: Key Research Reagent Solutions for PA Synthesis and Characterization

| Reagent/Material | Function in Protocol |

|---|---|

| Fmoc-Protected Amino Acids | Building blocks for the peptide sequence; Fmoc group protects the α-amine during chain elongation. |

| Rink Amide Resin | A common solid support that yields a C-terminal amide upon cleavage, a common feature in PAs. |

| Palmitic Acid | Source of the hydrophobic alkyl tail; coupled to the N-terminus of the assembled peptide. |

| Nile Red | A fluorescent dye used in an assay to monitor the critical aggregation concentration and self-assembly of PAs [5]. |

| Tris(2-carboxyethyl)phosphine (TCEP) | A reducing agent used to characterize the cleavage of disulfide-based, glutathione-responsive linkers in drug-delivery PAs [30]. |

Detailed SPPS Protocol for a Pro-Angiogenic PA

The following protocol outlines the step-by-step synthesis of a model PA, C16-VVVAAAGGRGDS, using standard Fmoc-SPPS procedures [5].

Experiment Title: Fmoc-Solid Phase Synthesis of a Bioactive Peptide Amphiphile. Objective: To synthesize and cleave a peptide amphiphile from solid support, yielding a crude product for subsequent purification and self-assembly testing. Materials: Rink Amide MBHA resin, Fmoc-protected amino acids (Fmoc-Ser(tBu)-OH, Fmoc-Gly-OH, Fmoc-Asp(OtBu)-OH, Fmoc-Arg(Pbf)-OH, Fmoc-Ala-OH, Fmoc-Val-OH), Palmitic acid, Deprotection reagent (20% Piperidine in DMF), Coupling reagents (HBTU and HOAt in DMF), Activator base (N,N-Diisopropylethylamine, DIPEA), Cleavage cocktail (Trifluoroacetic acid, TFA, with triisopropylsilane and water as scavengers), DMF, DCM, Diethyl ether.

Workflow:

- Resin Swelling: Place the Rink Amide resin (0.1 mmol) in a solid-phase reaction vessel. Add 5 mL of DCM and gently agitate for 30 minutes to swell the resin matrix. Drain the DCM.

- Fmoc Deprotection (Cycle): Add 5 mL of 20% piperidine in DMF. Agitate the mixture for 5 minutes, then drain. Repeat this step for a second 5-minute treatment. Drain completely and wash the resin thoroughly with DMF (5 x 1 minute washes).

- Amino Acid Coupling (Cycle): For each amino acid in the sequence (from C-terminal to N-terminal): a. Prepare a coupling solution: 4 equivalents of Fmoc-amino acid, HBTU, and HOAt in DMF, activated with 8 equivalents of DIPEA. b. Add the solution to the reaction vessel and agitate for 45-60 minutes. c. Drain the coupling solution and wash the resin with DMF (3 x 1 minute washes). d. Perform a Kaiser test to confirm complete coupling. If the test is positive (indicating free amines), repeat the coupling step. e. Perform steps 2 and 3 to deprotect the newly coupled amino acid and begin the next cycle.

- Palmitic Acid Coupling: After the final Fmoc deprotection (of the N-terminal Valine), couple palmitic acid using the same coupling procedure described in step 3, using 4 equivalents of palmitic acid.

- Final Cleavage and Deprotection: a. Wash the resin with DCM (3 x 1 minute) and dry it in vacuo. b. Prepare a cold cleavage cocktail (TFA/Triisopropylsilane/Water, 95:2.5:2.5). c. Add the cleavage cocktail to the dried resin (∼10 mL per gram of resin) and agitate for 3 hours at room temperature. d. Filter the mixture to separate the resin from the cleaved PA solution. Wash the resin with a small amount of fresh TFA.

- Precipitation and Isolation: a. Combine the TFA filtrates and concentrate the volume under a stream of nitrogen or by rotary evaporation. b. Precipitate the crude PA by slowly dripping the concentrated TFA solution into 40 mL of cold diethyl ether in a 50 mL centrifuge tube. c. Cool the tube at -20°C for 30 minutes to complete precipitation. d. Centrifuge the tube at 4000 rpm for 10 minutes to pellet the PA. Decant the ether supernatant. e. Wash the pellet with fresh cold ether and re-centrifuge. Decant the ether and dry the pellet under a vacuum to yield the crude PA as a white solid.

Flow Chemistry for Peptide Synthesis

While SPPS is highly effective, flow chemistry presents a modern alternative with potential for improved control and scalability. In continuous flow synthesis, reagent solutions are pumped through a temperature-controlled reactor, as opposed to the batch-wise process of SPPS. This can lead to more efficient mixing, superior heat and mass transfer, and the ability to integrate multiple synthetic and purification steps in a single, automated system. Although not explicitly detailed in the wound-healing context of the search results, the principles of flow chemistry are highly applicable to peptide synthesis and can be leveraged for producing PAs with higher reproducibility and at a larger scale.

Analytical Characterization of Synthesized PAs

Rigorous characterization is essential to confirm the identity, purity, and self-assembling properties of the synthesized PA.

Table 2: Key Analytical Methods for Peptide Amphiphile Characterization

| Analytical Method | Measurable Parameters | Application in PA Development |

|---|---|---|

| Liquid Chromatography-Mass Spectrometry (LC-MS) | Molecular weight, Purity [5]. | Confirms the successful synthesis of the target PA and assesses crude product purity before purification. |

| Circular Dichroism (CD) | Secondary structure (e.g., β-sheet formation) [5]. | Monitors the internal ordering of PA molecules during assembly; a shift towards a β-sheet signature indicates successful nanofiber formation. |

| Transmission Electron Microscopy (TEM) | Nanofiber morphology, diameter, and length [5]. | Directly visualizes the supramolecular structure of the assembled PA nanofibers. |

| Rheology | Storage (G') and Loss (G'') moduli, viscoelasticity [5]. | Quantifies the mechanical strength and shear-thinning behavior of the PA hydrogel, critical for sprayability and scaffold stability. |

Detailed Protocol: Confirming Self-Assembly via Circular Dichroism (CD) Spectroscopy Objective: To characterize the secondary structure of the PA in solution and confirm β-sheet formation. Materials: Purified PA powder, Ultrapure water, Phosphate Buffered Saline (PBS), 0.1 M NaOH, 0.1 M HCl, CD spectrometer quartz cuvette (path length 0.1 cm or 1 mm). Workflow:

- Sample Preparation: Dissolve the PA in ultrapure water at a concentration of 0.1% (w/v) by gently vortexing. The solution may be sonicated in a cold water bath for 10 minutes to aid dissolution.

- Triggering Assembly: Add a calculated volume of 10X PBS to the PA solution to achieve a final 1X PBS concentration, thereby triggering self-assembly via charge screening. Gently mix and allow the solution to incubate at room temperature for 1 hour.

- CD Measurement: Load the assembled PA solution into a quartz cuvette. Acquire the CD spectrum at room temperature over a wavelength range of 190-260 nm.

- Data Analysis: A characteristic signature for β-sheet structure is a positive peak near 195 nm and a negative peak near 218 nm. Compare the spectrum of the assembled PA to that of the unassembled PA in pure water to confirm the structural transition.

Application Protocol: Forming and Testing Sprayable PA Gels

The ultimate test for a wound-healing PA is its functionality as a sprayable scaffold that supports cellular processes.

Detailed Protocol: Spray Delivery and Angiogenesis Assay Objective: To form a PA hydrogel via ionic crosslinking, assess its sprayability, and evaluate its pro-angiogenic potential. Materials: Sterile PA solution (1% w/v in water), Sterile CaCl₂ solution (100 mM in water), Spray device (e.g., dual-barrel syringe or airbrush), Human Umbilical Vein Endothelial Cells (HUVECs), Matrigel, Cell culture incubator. Workflow:

- Gelation and Spraying: a. Load the sterile PA solution into one syringe and the sterile CaCl₂ solution into a second syringe. b. Connect the syringes via a luer-lock connector or a spray head designed for mixing. c. Depress the plungers simultaneously to mix the PA and crosslinker upon ejection, resulting in the instantaneous formation of a gel that can be sprayed directly onto a surface (e.g., an in vitro wound model or a material for rheological testing) [5] [22].

- Endothelial Cell Tube Formation Assay: a. Thaw Matrigel on ice and pipet it into a pre-chilled 96-well plate. Allow it to polymerize for 30 minutes at 37°C. b. Prepare two test conditions: 1) PA nanofiber gel formed in cell culture medium, and 2) Control (medium only). c. Seed HUVECs onto the surface of the Matrigel and the test PA gel. d. Incubate the cells for 6-18 hours at 37°C and 5% CO₂. e. Image the cells using an inverted microscope. Quantify the total tube length, number of branch points, and number of meshes per field of view. A significant increase in these parameters in the PA gel condition indicates enhanced in vitro angiogenesis, a critical process for wound healing [5].

Pathway and Workflow Diagrams

The following diagrams summarize the key signaling pathways involved in wound healing and the experimental workflow for PA development.

Diagram 1: PAs in wound healing pathways. Peptide amphiphile nanofibers (red and green) positively influence the natural wound healing process by scavenging harmful ROS and presenting signals that enhance fibroblast activity.

Diagram 2: PA development workflow. The linear workflow for developing a sprayable PA wound therapy, from molecular design to functional testing.

Electrospinning and Alternative Methods for Nanofiber Production

Nanofibers have emerged as a pivotal component in advanced biomedical research due to their high surface area-to-volume ratio, porosity, and ability to mimic the native extracellular matrix (ECM) [31] [32]. These properties are particularly valuable in wound healing applications, where nanofibrous scaffolds can promote cell adhesion, proliferation, and migration [33]. For researchers focused on developing sprayable peptide amphiphile (PA) nanofibers for wound healing, understanding the fabrication landscape is essential for selecting appropriate manufacturing strategies. This document provides a comprehensive technical comparison of prominent nanofiber production methods, with emphasis on their applicability to wound healing research, particularly for creating advanced, functionalized wound dressings.

The two primary approaches for nanofiber fabrication are electrospinning (a fiber production method) and molecular self-assembly (a bottom-up synthetic approach). Electrospinning utilizes electrical forces to draw charged threads from polymer solutions, producing fibrous mats with diameters ranging from nanometers to several micrometers [34] [32]. In contrast, molecular self-assembly relies on supramolecular chemistry to create nanofibers through the spontaneous organization of molecules under specific thermodynamic conditions [3] [30]. For research involving sprayable PA nanofibers, both approaches offer distinct advantages: electrospinning provides robust structural scaffolds, while self-assembling PAs enable precise biochemical signaling and minimally invasive application.

Comparative Analysis of Nanofiber Fabrication Methods

Table 1: Technical Comparison of Primary Nanofiber Fabrication Methods

| Parameter | Electrospinning | Molecular Self-Assembly | Phase Separation | Template Synthesis |

|---|---|---|---|---|

| Fiber Diameter | 50 nm - 5 μm [33] [32] | 5 - 20 nm [3] [30] | 50 - 500 nm [31] | >50 nm [31] |

| Principal Driving Force | High-voltage electric field [34] [32] | Non-covalent interactions (hydrogen bonding, hydrophobic collapse, electrostatic) [3] | Thermodynamic parameters and solvent-non-solvent interactions [31] | Filtration through porous membrane [31] |