Aerogel vs. Traditional Insulation: A Scientific Breakdown for Advanced Material Applications

This article provides a comprehensive, science-driven analysis for researchers and technical professionals comparing next-generation aerogel insulation with traditional materials.

Aerogel vs. Traditional Insulation: A Scientific Breakdown for Advanced Material Applications

Abstract

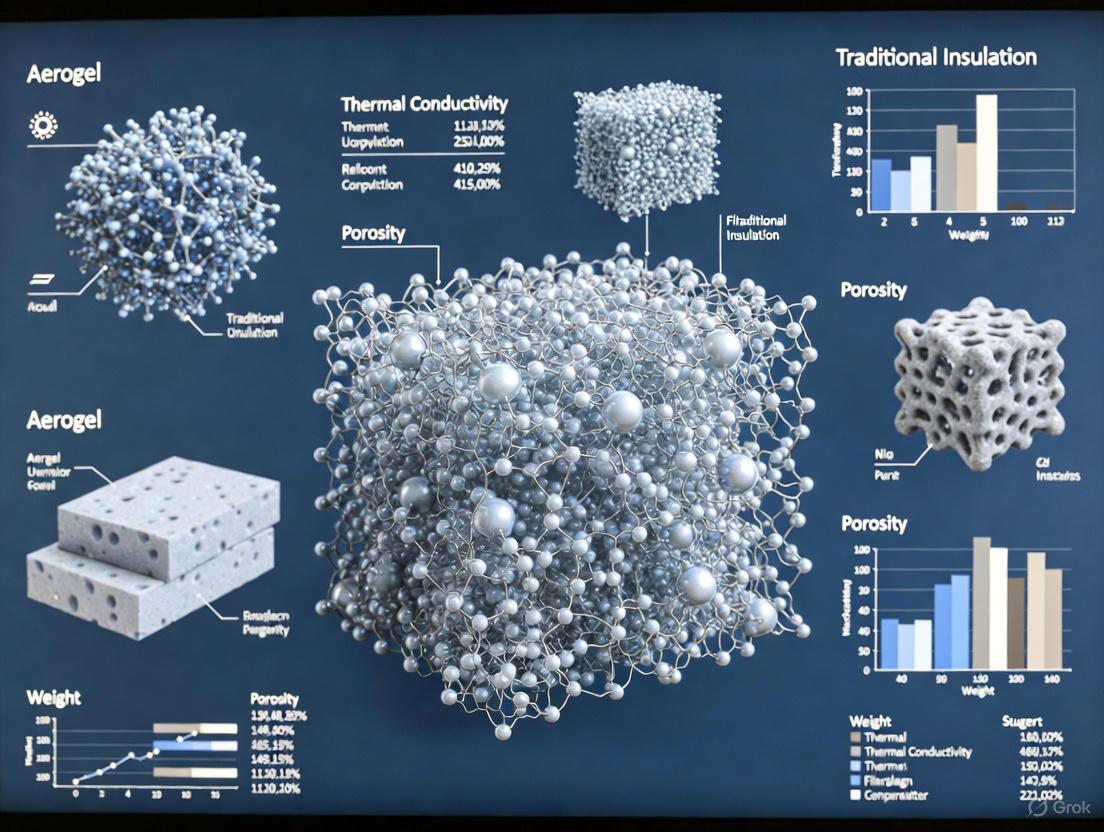

This article provides a comprehensive, science-driven analysis for researchers and technical professionals comparing next-generation aerogel insulation with traditional materials. We examine the fundamental material science, including nanostructure and thermal conductivity mechanisms. The analysis covers advanced manufacturing techniques, real-world performance validation across industries like EV batteries and construction, and addresses key challenges such as production scalability and mechanical fragility. Finally, we explore emerging applications in biomedical fields, including drug delivery and tissue engineering, positioning aerogels as a transformative multi-functional material for future R&D.

The Material Science Foundation: Deconstructing Aerogel Nanostructure and Traditional Insulation Mechanisms

The pursuit of energy efficiency and thermal performance in building design, industrial applications, and scientific equipment has elevated the importance of advanced insulation materials. This guide provides a systematic comparison of traditional insulation materials, such as fiberglass and foams, against innovative aerogel technology, framing the analysis within the broader context of materials science research. The performance of these materials is primarily governed by their thermal conductivity, with lower values indicating superior insulating performance [1]. While traditional materials have long been the standard due to their cost-effectiveness and established manufacturing processes, aerogels represent a significant leap in insulation technology, offering exceptional thermal resistance in extremely thin profiles [2]. This analysis synthesizes current experimental data and research trends to offer researchers and scientists a clear, objective evaluation of these competing material systems, focusing on quantitative performance metrics, experimental methodologies for characterization, and emerging applications.

Material Contenders at a Glance

The following table summarizes the core properties of the primary insulation materials discussed in this guide, providing a high-level overview for initial comparison.

Table 1: Core Properties of Insulation Materials for Research Applications

| Material | Typical Thermal Conductivity (W/m·K) | Typical Density (kg/m³) | Key Characteristics | Primary Research Applications |

|---|---|---|---|---|

| Silica Aerogel | 0.011 - 0.020 [3] [4] [1] | <40 - 80 [3] [5] | Ultra-lightweight, highly porous (>99%), nanoporous structure [3] [4] | High-performance building envelopes, nuclear pipeline insulation, cryogenics [6] [3] |

| Fiberglass (Standard) | 0.030 - 0.040 [1] [2] | 9 - 16 [7] | Fibrous, non-combustible, cost-effective [1] | General building insulation, thermal and acoustic buffering |

| Fiberglass (High-Density) | 0.021 - 0.029 (estimated from R-value) [7] | 24 - 32 [7] | Higher R-value per unit thickness, improved sound control [7] | Space-constrained builds requiring higher performance |

| Spray Foam (Open-Cell) | 0.040 (approx.) [1] | 8 - 12 (approx.) | Expands to fill cavities, good air sealing [1] | Residential wall cavities, attic insulation |

| Spray Foam (Closed-Cell) | 0.022 - 0.028 (approx.) [1] | 30 - 50 (approx.) | High R-value, adds structural strength, moisture-resistant [1] | Roofing, below-grade insulation, high-humidity environments |

| Cellulose | 0.035 - 0.040 [1] | 25 - 50 (approx.) | Composed of recycled paper, eco-friendly [1] [8] | Blown-in attic insulation, wall retrofits |

Quantitative Performance Comparison

For research and development purposes, a deeper understanding of material performance across multiple metrics is essential. The following table consolidates key quantitative data from recent studies and industry specifications to facilitate direct comparison.

Table 2: Comprehensive Performance and Experimental Data for Insulation Materials

| Material | Thermal Conductivity (W/m·K) | R-Value per Inch (hr·ft²·°F/BTU) | Compressive Strength | Fire Resistance | Moisture Response |

|---|---|---|---|---|---|

| Silica Aerogel | 0.011 (Powder) [3] - 0.024 (Blanket) [4] | R-10 to R-20 (calculated) | Low (standalone) [9], Enhanced in composites (e.g., 1.2 - 8.3 MPa) [9] | High (inorganic base) [5] | Hydrophobic, minimal impact on performance [2] |

| Fiberglass (Standard) | 0.030 - 0.040 [1] [2] | R-2.9 to R-3.3 [7] | Not Structural | Non-combustible [1] | Can absorb moisture, leading to performance loss [1] |

| Fiberglass (High-Density) | Information Missing | R-4.2 to R-5.0 [7] | Not Structural | Non-combustible [7] | Improved moisture resistance over standard [7] |

| Spray Foam (Closed-Cell) | 0.022 - 0.028 [1] | R-6.0 to R-7.0 (approx.) | Adds structural strength [1] | Often includes fire retardants [1] | Highly moisture-resistant [1] |

| Cellulose | 0.035 - 0.040 [1] | R-3.2 to R-3.8 (approx.) | Not Structural | Treated with fire retardants [1] | Can absorb moisture, may settle over time [1] |

| Aerogel-Cement Composite | 0.065 - 0.400 [9] | R-1.4 to R-8.7 (calculated) | 1.2 - 8.3 MPa [9] | High (inorganic matrix) | Durability maintained in freeze-thaw cycles [9] |

Experimental Protocols and Methodologies

Thermal Conductivity Measurement via Heat Flow Meter

The thermal conductivity of insulating materials like aerogel blankets and fiberglass boards is commonly determined using a Heat Flow Meter (HFM) in accordance with ASTM C518-15 [4]. This method establishes a steady-state, one-dimensional heat flux through a flat slab specimen.

- Procedure: The specimen is placed between two parallel plates maintained at constant but distinct temperatures (e.g., 10°C and 30°C). The instrument's plates automatically adjust to the sample's thickness. Once steady-state conditions are achieved, the heat flux through the sample, the plate separation (sample thickness), and the temperature difference are measured.

- Calculation: Thermal conductivity (λ) is calculated using Fourier's law of heat conduction, incorporating the calibrated heat flux, temperature gradient, and material thickness [4].

- Apparatus: Instruments like the Thermtest HFM are designed for this purpose, with an reported accuracy of ≤3% and precision of ≤0.5% for materials with thermal conductivities between 0.005 and 0.5 W/m·K [4].

Deep Learning-Driven Thermal Conductivity Evaluation

For materials in service under extreme conditions, such as aerogel composites in nuclear power pipelines, non-destructive evaluation methods are critical. A novel approach uses Graph Neural Networks (GNNs) to predict thermal conductivity based on accessible physical measurements [6].

- Node Feature Construction: A graph dataset is created where nodes represent data points. Node features include the heating surface temperature, the back-surface temperature of the aerogel composite felt, ambient temperature, and humidity [6].

- Graph Formation: Nodes are connected based on shared features, such as insulation felt thickness, to create a graph structure that captures complex, non-linear relationships [6].

- Model and Training: A dual-channel model is employed. A Graph Transformer captures global features via an attention mechanism, while a Generalized PageRank GNN (GPR-GNN) captures local graph structures. This model is trained on historical service data to learn the mapping between temperature/humidity profiles and thermal conductivity, eliminating the need for destructive specimen extraction [6].

Synthesis and Testing of Aerogel-Composite Materials

Research into integrating aerogel into matrices like cement involves specific protocols for evaluating mechanical and thermal properties.

- Specimen Fabrication (Aerogel-Cement): Ductile aerogel powder cement-based composites (DACC) are fabricated by mixing aerogel powder into a cementitious matrix, often with polyvinyl alcohol (PVA) fibers to enhance ductility. Specimens are molded, compressed, and dried at 60°C for 48 hours before curing [9].

- Pore Structure Analysis: Mercury Intrusion Porosimetry (MIP) is used to characterize the pore structure of composites, providing data on porosity, average pore size, and pore size distribution, which directly influence thermal and mechanical properties [9].

- Mechanical and Durability Testing: Standard compressive and flexural strength tests are performed. Durability is assessed through methods like freeze-thaw cycling, where the mass loss and strength retention of samples are measured after multiple cycles [9].

Research Reagents and Materials Toolkit

For scientists designing experiments involving advanced insulation materials, the following table outlines key materials and their functions as derived from the cited research.

Table 3: Essential Research Reagents and Materials for Insulation Studies

| Material/Reagent | Function in Research Context | Example Application |

|---|---|---|

| Powdered Silica Aerogel | The primary insulating agent due to its nanoporous structure and ultra-low thermal conductivity. | Functional filler in cement composites [9] and cellulose matrices [3] to drastically reduce thermal conductivity. |

| Expandable Graphite | Acts as a flame retardant additive; expands upon heating to form a protective char layer. | Improves fire resistance in cellulose-based composite insulation panels [3]. |

| Ceramic Binder | An inorganic binder providing structural integrity and enhanced fire resistance to composite materials. | Used to bond aerogel and cellulose in composite insulation specimens [3]. |

| Polyvinyl Alcohol (PVA) Fibers | Enhances the tensile strength, ductility, and crack resistance of brittle composite matrices. | Incorporated into aerogel-cement composites to create ductile aerogel cement composites (DACC) [9]. |

| Cardboard-Derived Cellulose | A sustainable, recycled base material derived from pulped cardboard for creating eco-friendly composites. | Serves as the main matrix material for porous, lightweight insulation panels when mixed with aerogel [3]. |

Visualization of Experimental Workflows

The following diagrams illustrate key experimental and data analysis processes described in this guide.

Aerogel Composite Analysis Workflow

Deep Learning Prediction Model

The data and methodologies presented in this guide objectively delineate the performance boundaries between traditional insulation materials and advanced aerogel technology. Aerogels unequivocally offer superior thermal resistance per unit thickness, a critical property for space-constrained and high-performance applications. However, traditional materials like fiberglass and spray foam remain highly relevant, offering robust, cost-effective solutions for less demanding scenarios. The ongoing integration of aerogels into composite systems, such as aerogel-cement and aerogel-cellulose, represents a promising research vector, aiming to balance exceptional insulation with improved mechanical properties and manufacturability. For researchers, the choice of material is not a simple substitution but a strategic decision based on a clear understanding of the trade-offs between thermal performance, mechanical integrity, cost, and application-specific requirements.

Aerogels are nanostructured materials characterized by an ultra-porous, three-dimensional network where the dispersing medium is gas, resulting in some of the lowest solid densities known to materials science [10] [11]. This nanoscale architecture, often comprising 90–99.8% air by volume, is directly responsible for the material's exceptional performance profile, including its legendary status as the best solid thermal insulator known [12]. The term "frozen smoke" aptly describes its spectral appearance, a visual testament to its ethereal porosity [12]. The performance of any aerogel—be it silica-based, polymer-based, carbon, or biopolymer—is not a product of its chemical composition alone but is fundamentally dictated by the intricate, porous nanostructure meticulously engineered through sol-gel chemistry and preserved via specialized drying techniques [13] [10]. This guide delves into the core relationship between this nanoscale architecture and the resulting macroscopic performance, providing researchers with a structured comparison to traditional insulation materials and the experimental protocols needed to characterize them.

Performance Comparison: Aerogel vs. Traditional Insulation Materials

The properties of aerogels are a direct physical manifestation of their nanoscale architecture. The extremely high porosity and nanopore sizes (typically 5-50 nm) dramatically reduce heat transfer by minimizing solid conduction, suppressing gaseous convection, and scattering photons [14]. Similarly, the vast internal surface area (often exceeding 600 m²/g) enables remarkable performance in applications like drug delivery and catalysis [13] [10]. The following tables provide a quantitative comparison of key properties between aerogels and traditional alternatives.

Table 1: Comparative Analysis of Fundamental Material Properties

| Property | Silica Aerogel | Fiberglass | Expanded Polystyrene (EPS) | Mineral Wool |

|---|---|---|---|---|

| Density (kg/m³) | 3–500 [10] | 10–120 [15] | 15–30 [15] | 20–200 [15] |

| Porosity (%) | 95–99.8 [12] [16] | N/A | N/A | N/A |

| Specific Surface Area (m²/g) | 150–1000 [13] [16] | Low (Typically <5) | Low (Typically <1) | Low (Typically <5) |

| Primary Pore Size | Nanoscale (5–50 nm) [14] | Macroscale (Fibrous) | Macroscale (Cellular) | Macroscale (Fibrous) |

Table 2: Comparative Analysis of Functional Performance Properties

| Performance Metric | Silica Aerogel | Fiberglass | Expanded Polystyrene (EPS) | Mineral Wool |

|---|---|---|---|---|

| Thermal Conductivity (W/m·K) | 0.012–0.020 [12] [17] | 0.030–0.040 [2] | 0.030–0.040 [15] | 0.030–0.040 [2] |

| Moisture Resistance | Excellent (Inherently Hydrophobic) [12] [2] | Poor (Absorbs moisture) [2] | Good [15] | Poor (Absorbs moisture) [2] |

| Fire Retardancy | Excellent (Withstands up to 1000°C) [12] | Good | Poor (Melts and releases toxic gases) | Excellent |

| Compressive Strength | Low (Pure), Improved in Composites [17] [11] | N/A (Non-structural) | Medium | N/A (Non-structural) |

| Key Performance Driver | Nanoscale pores suppress all heat transfer modes [14]. | Trapped air in fibrous matrix. | Trapped air in closed cells. | Trapped air in fibrous matrix. |

Experimental Protocols: Probing the Nanoscale

Understanding and validating the structure-property relationship of aerogels requires a suite of characterization techniques. The following are detailed methodologies for key experiments cited in comparative analyses.

Protocol for Thermal Conductivity Measurement

Objective: To determine the effective thermal conductivity (keff) of an aerogel sample under ambient conditions, a critical parameter for insulation performance [14].

Methodology:

- Sample Preparation: Cut the aerogel monolith or composite to fit the specific dimensions of the chosen testing apparatus (e.g., a guarded hot plate or heat flow meter). Ensure the surfaces are parallel and smooth.

- Instrument Calibration: Calibrate the thermal conductivity meter using standard reference materials with known thermal properties.

- Measurement Setup: Place the sample between a hot and a cold plate, establishing a steady, one-dimensional heat flux through the sample. The standard test condition is often a mean temperature of 24°C with a temperature gradient of 10–20°C.

- Data Acquisition: Apply the temperature gradient and allow the system to reach steady state. The instrument measures the heat flux (Q) through the sample, the thickness (L), and the temperature difference (ΔT) across it.

- Calculation: The thermal conductivity (k) is calculated using Fourier's law: ( k = \frac{Q \cdot L}{\Delta T} ), where the result is reported in W/m·K. Multiple measurements should be taken to ensure reproducibility [15] [14].

Protocol for Microstructural Analysis via Gas Sorption

Objective: To characterize the porous network of the aerogel, including specific surface area, pore volume, and pore size distribution [13].

Methodology:

- Sample Outgassing: A small, precisely weighed aerogel sample is placed in a sealed tube and heated under vacuum (e.g., 150°C for 12 hours) to remove any adsorbed moisture or contaminants from the surface.

- Cryogenic Conditions: The sample tube is then immersed in a cryogenic bath (typically liquid nitrogen at 77 K).

- Gas Adsorption: An inert gas (usually N₂) is introduced into the sample tube in controlled increments. At each step, the pressure is measured, and the quantity of gas adsorbed by the sample is determined.

- Data Analysis: The resulting adsorption-isotherm data is analyzed using theoretical models like the Brunauer-Emmett-Teller (BET) theory to calculate the specific surface area. The pore size distribution is typically derived from the adsorption branch of the isotherm using methods such as Barrett-Joyner-Halenda (BJH) or Non-Local Density Functional Theory (NLDFT) [13].

Protocol for Fabricating a Fiber-Reinforced Aerogel Composite

Objective: To synthesize a mechanically robust aerogel composite with enhanced thermal and structural properties, addressing the inherent brittleness of pure silica aerogel [17] [14].

Methodology:

- Sol Preparation: Hydrolyze a silica precursor, such as Tetraethyl orthosilicate (TEOS), in a mixture of ethanol, water, and a catalytic acid (e.g., acetic acid) to form a silica sol.

- Fiber Incorporation: Immerse a porous, ultra-light glass fiber wool (UGFW) felt substrate into the prepared sol. Ensure complete infiltration.

- Gelation and Aging: Induce gelation within and around the fiber network by adding a base catalyst like ammonium hydroxide. The resulting wet gel is then aged in the solution for 24-48 hours to strengthen the network.

- Surface Modification (Hydrophobization): Exchange the pore liquid with a hydrophobic agent, such as Hexamethyldisilazane (HMDS), in an organic solvent like acetonitrile. This step passivates the silica surface, making it hydrophobic.

- Drying: Dry the gel using a supercritical CO₂ drying process. The sample is placed in a high-pressure vessel, and liquid CO₂ is used to displace the solvent. The vessel is then brought above the critical point of CO₂ (31.1°C, 73.9 bar), and the supercritical fluid is slowly vented off, avoiding liquid-vapor meniscus and thus preserving the nanostructure.

- Outcome: The final product is a flexible, hydrophobic aerogel composite (SA@UGFW) with a sandwich structure, exhibiting improved compressive strength (~0.1 MPa) while maintaining low thermal conductivity and high surface area (~500 m²/g) [17].

Visualizing the Structure-Performance Relationship

The logical pathway from nanoscale architecture to macroscopic performance is governed by fundamental principles of heat and mass transfer. The following diagram maps this critical relationship.

The Scientist's Toolkit: Essential Research Reagents & Materials

The synthesis and characterization of aerogels require specific chemical precursors and instrumentation. The table below details essential items for a research laboratory focused on aerogel technology.

Table 3: Key Research Reagent Solutions for Aerogel Synthesis and Analysis

| Reagent / Material | Function in Research | Specific Example |

|---|---|---|

| Tetraethyl Orthosilicate (TEOS) | A common molecular precursor for creating the silica (SiO₂) sol-gel network via hydrolysis and condensation reactions [17]. | Used in the protocol for fiber-reinforced composites (Section 3.3). |

| Hexamethyldisilazane (HMDS) | A functional silane used for surface modification (silylation) to impart hydrophobicity and improve mechanical stability during drying [17]. | Critical for ambient pressure drying; replaces surface silanol (Si-OH) groups with non-polar trimethylsilyl groups. |

| Polyimide (PI) Precursors | Used to synthesize polymer-based aerogels, which offer superior mechanical flexibility compared to silica [11]. | Components like polyamic acid are used to create aerogels with high thermal stability and strength. |

| Ultra-Light Glass Fiber Wool (UGFW) | A fibrous substrate used as a scaffold to reinforce the brittle aerogel matrix, enhancing mechanical integrity [17]. | Serves as the base material in the SA@UGFW composite protocol (Section 3.3). |

| Graphene Oxide (GO) / Nanotubes | Nanocarbon additives used to enhance electrical conductivity, mechanical strength, or to act as radiative opacifiers [14]. | Incorporated into aerogel matrices to create conductive composites or to block infrared radiation. |

| Supercritical CO₂ Dryer | Essential instrumentation for removing the solvent from the wet gel without collapsing the delicate nanoporous structure [10] [11]. | The industry standard for producing high-quality, low-shrinkage aerogels. |

Core Principles of Thermal Insulation in Solids and Gases

The pursuit of energy efficiency and sustainable building practices has placed a strong emphasis on advancing thermal insulation technologies. Within this context, aerogel technology has emerged as a leading contender, challenging the dominance of traditional insulation materials. This guide provides an objective, data-driven comparison of these material classes, framing the analysis within ongoing research on their fundamental operational principles and performance. The core objective is to delineate the scientific basis for thermal insulation and evaluate how different materials inhibit heat flow, supported by experimental data and detailed methodologies relevant to researchers and scientists.

Fundamental Principles of Thermal Insulation

Thermal insulation functions by impeding the transfer of heat, which occurs through three primary mechanisms: conduction, convection, and radiation [18].

Conduction is the transfer of kinetic energy through a material via molecular collisions. It is the dominant form of heat transfer through solid materials and is quantified by a material's thermal conductivity (λ-lambda). A lower λ-value indicates a better insulating capability [18].

Convection involves heat transfer through the bulk movement of a fluid (air or liquid). In insulation, this is minimized by creating small, discontinuous pockets of gas that disrupt the buoyancy-driven flow of air [18].

Radiation is the transfer of heat by electromagnetic waves. In high-temperature applications or materials with high porosity, radiative heat transfer becomes more significant.

The overall thermal performance of an insulation material in a specific application is expressed as its Thermal Resistance or R-value, which incorporates both the material's thermal conductivity and its thickness. The relationship is given by: Thermal Resistance (R) = Thickness (m) / Thermal Conductivity (W/m·K) [18]. A higher R-value signifies superior insulating performance.

Material Comparison and Performance Data

Quantitative Performance of Insulation Materials

The following table summarizes the key thermal properties of aerogel and traditional insulation materials, providing a basis for direct comparison.

Table 1: Thermal Properties of Insulation Materials [19] [20] [21]

| Material | Thermal Conductivity (λ) (W/m·K) | Typical R-Value per Inch (hr·ft²·°F/Btu) | Density (kg/m³) | Primary Composition |

|---|---|---|---|---|

| Silica Aerogel | 0.011 - 0.020 [3] [19] | ~10.3 [22] | <40 - 100 [3] [19] | Silica (SiO₂) nanostructure |

| Aerogel Blanket | 0.015 - 0.025 [19] [23] | N/A | ~100 [19] | Aerogel + fibrous matrix |

| Polyurethane Foam (Closed-cell) | 0.022 - 0.035 [20] [24] | 6.0 - 7.0 [20] | ~30 (varies) | Organic polymer foam |

| Polystyrene (XPS) | ~0.035 [18] | 5.0 [20] | 28 - 45 [18] | Organic polymer foam |

| Cellulose (Blown) | 0.035 - 0.040 [18] | 3.2 - 3.8 [20] | 27 - 65 [18] | Recycled paper fiber |

| Wood Fiber | 0.038 [18] | N/A | 50 - 160 [18] | Natural wood fiber |

| Fiberglass | 0.035 - 0.040 [18] [25] | 3.1 - 3.4 [20] | 10 - 50 (for batts) [18] | Glass fibers |

| Mineral Wool | 0.035 - 0.040 [24] [18] | N/A | 23 - 80 [18] | Rock or slag fibers |

Comparative Analysis of Key Attributes

Table 2: Performance and Safety Attribute Comparison [20] [21] [22]

| Attribute | Aerogel | Fiberglass | Cellulose | Polyurethane Foam |

|---|---|---|---|---|

| Fire Resistance | Excellent (inorganic) [21] | Good (non-flammable) [21] | Good (with fire retardants) [21] | Poor (requires additives) [21] [24] |

| Moisture Resistance | Excellent (hydrophobic) [19] [21] | Poor (absorbs moisture) [24] | Poor (absorbs moisture) [20] | Excellent (closed-cell) [24] |

| Longevity/Durability | Excellent (does not settle) [21] | Fair (can settle over time) [20] | Fair (can settle over time) [20] | Good (maintains shape) [24] |

| Environmental Impact | Evolving production [21] | Energy-intensive production [21] | Excellent (recycled content) [21] | Not eco-friendly [21] |

| Handling/Safety | Requires PPE (respiratory irritation) [22] | Requires PPE (skin/lung irritation) [21] | Minimal risk [21] | Professional installation recommended [25] |

Experimental Protocols and Research Methodologies

Protocol: Fabrication of Cellulose-Aerogel Composite Insulation

This protocol is adapted from a 2024 study evaluating the thermal insulation performance of cellulose-based silica aerogel composites [26] [3].

Objective: To fabricate and test composite insulation panels from recycled cardboard and silica aerogel powder.

Materials (Research Reagent Solutions):

- Cellulose Raw Material: Recycled cardboard, pulped into fine particles [26] [3].

- Silica Aerogel Powder: White, translucent powder with a thermal conductivity of ~0.011 W/mK, porosity >99%, and density <40 kg/m³ [3].

- Ceramic Binder: Composed primarily of MgO, SiO₂, and Al₂O₃, used at 30 wt% to provide structural integrity and fire resistance [26] [3].

- Expandable Graphite (100-mesh): Added at 40 wt% as a flame retardant, which expands upon heating to form a protective char layer [26] [3].

- Deionized Water: Used in the pulping and mixing process.

Methodology:

- Pulping: Shred and pulp the recycled cardboard into fine particles in an aqueous solution [26] [3].

- Mixing:

- Molding and Compression: Transfer the mixture into a standard 100 mm x 100 mm panel mold. Compress the material using an electric compressor to achieve the desired density and panel form [26] [3].

- Drying and Curing: Dry the molded specimens in a controlled oven at 60°C for 48 hours to remove moisture [26] [3].

- Conditioning: Condition the dried specimens in a constant temperature and humidity chamber (23 ±2°C, 50 ±5% relative humidity) for 48 hours prior to testing to ensure stability [26] [3].

Workflow Diagram:

Protocol: Thermal Performance Measurement

Objective: To determine the thermal conductivity and diffusivity of the fabricated composite specimens.

Standard: ISO 22007-2 (for solids, paste, and powders) [26] [3].

Method: The transient plane source (TPS) method is commonly used. A planar sensor, acting as both a heat source and a resistance thermometer, is placed between two identical samples. A constant electrical power is applied to the sensor, generating heat that flows into the samples. The resulting temperature increase of the sensor is recorded over time. The thermal conductivity and diffusivity are simultaneously calculated from the temperature-time relationship [26] [3].

Key Parameters Measured:

- Thermal Conductivity (λ): The primary indicator of a material's ability to conduct heat.

- Thermal Diffusivity: The measure of how quickly a material can adjust its temperature to that of its surroundings.

Findings: The incorporation of aerogel improved the thermal insulation performance of the pure control and experimental groups by 16.66%, and the mixed control and experimental groups by 17.06% [26] [3].

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Key Research Materials for Insulation Development

| Material/Reagent | Function in Research | Key Characteristics |

|---|---|---|

| Powdered Silica Aerogel | The active insulating component in composites; its nanoporous structure is critical for reducing thermal conductivity [3]. | Very low density (<40 kg/m³), high porosity (>99%), ultra-low thermal conductivity (~0.011 W/mK) [3]. |

| Expandable Graphite | A flame-retardant additive that expands when heated, forming an intumescent char layer that delays fire spread [26]. | Expands several hundred times upon heating; reduces Heat Release Rate (HRR) and Total Heat Release (THR) in composites [26] [3]. |

| Ceramic Binder | An inorganic binder that provides structural integrity and enhances fire resistance in composite specimens [26] [3]. | Typically composed of metal oxides (e.g., MgO, SiO₂, Al₂O₃); withstands high temperatures [26] [3]. |

| Surfactant Micelles (e.g., SDS) | Used as a template in the sol-gel process to modify aerogel surface chemistry and control pore size during ambient pressure drying [19]. | Hydrophobic properties help maintain aerogel nanostructure during drying; minimizes pore size [19]. |

Mechanisms and Material Structures

The superior performance of aerogels can be understood by examining their structure. The following diagram illustrates the fundamental mechanisms of heat transfer and how different material architectures impede them.

The experimental data and comparative analysis confirm that aerogel technology represents a significant advancement in insulation material science. Its defining characteristic is an nanoporous solid structure that delivers ultra-low thermal conductivity (~0.011-0.020 W/m·K), substantially outperforming traditional materials like fiberglass and cellulose [19] [3]. While challenges remain regarding production costs and specific handling requirements, the integration of aerogel as a component in composites, such as aerogel-enhanced blankets and cellulose matrices, demonstrates a viable path for enhancing performance in specialized applications. For the research community, the ongoing work focuses on optimizing the synthesis for cost-effective scaling, developing novel composite architectures, and further enhancing fire-retardant properties without compromising the exceptional thermal performance that defines this material class.

This guide provides an objective comparison of the key material properties—thermal conductivity, density, and porosity—between innovative aerogel technology and traditional insulation materials. The data and experimental methodologies presented are intended to inform material selection and research directions for scientists and engineers.

Quantitative Comparison of Insulation Materials

The following tables summarize core properties and performance data for a range of insulation materials, from traditional options to advanced aerogels.

Table 1: Core Material Properties of Insulation Materials

| Material Category | Specific Material | Thermal Conductivity (W/m·K) | Density (kg/m³) | Porosity (%) | Key Characteristics |

|---|---|---|---|---|---|

| Aerogel & Composites | Silica Aerogel (Ambient) | < 0.020 [14] | Variable (e.g., ~200 [27]) | >90% [28] | Nanoporous structure, ultra-low conductivity. |

| Silica Aerogel (Fiber-reinforced) | As low as 0.016 [14] | Varies with fiber type/loading | High, tunable [14] | Enhanced mechanical strength, reduced radiative heat transfer. | |

| Pyrogel-type Aerogel | Slight increase (~5%) after 250°C annealing [29] | Not Specified | Not Specified | Good thermal stability up to 250°C. | |

| Advanced Inorganics | Porous Geopolymer | 0.00998 [30] | 525 [30] | 68.3 [30] | Salt-activated, made from ceramic waste. |

| Light-weight Porous Ceramic (Dolomite-Granite) | ~0.1 (estimated from data) [31] | ~525 [31] | High closed-cell [31] | Made from solid waste, high closed-pore porosity. | |

| Sawdust-Clay Composite | 0.044 [32] | Not Specified | Not Specified | Eco-friendly, low-cost composite. | |

| Traditional & Organic | Advanced Flexible Reusable Surface Insulation (AFRSI) | 0.033 [27] | 128 [27] | Not Specified | Ceramic fiber felt for aerospace. |

| Still Air (for reference) | 0.026 [14] | ~1.2 | - | Baseline for performance comparison. | |

| Fiberglass / Foam | 0.030 - 0.040 [2] | Variable | Variable | Common traditional insulation. |

Table 2: Performance Data under Specific Experimental Conditions

| Material | Test Conditions | Key Performance Outcome | Experimental Methodology |

|---|---|---|---|

| Sawdust-Clay Composite | Field test in hot-arid climate; 20% sawdust + 80% clay mix [32]. | Reduced cooling energy consumption by up to 37% compared to uninsulated baseline [32]. | Three test rooms built; power consumption monitored over 22 days under varying weather [32]. |

| Fiber-Aerogel Composite | Incorporation of ~10% fiber volume fraction [14]. | Thermal conductivity reduced by up to 30%; radiative heat transfer reduced by ~40% [14]. | FTIR spectroscopy to measure emissivity/transmittance; numerical heat transfer models [14]. |

| Pyrogel-type Aerogel | Thermal annealing at 250°C for 1 day [29]. | Thermal conductivity increased by ~5%; specific heat capacity increased by ~6% [29]. | Thermal analysis pre-/post-annealing; micro/macro-structural characterization (XRD, DSC, IR) [29]. |

| Light-weight Porous Ceramic | Sintering with SiC foaming agent [31]. | Achieved low density (~525 kg/m³) and high closed-pore porosity for good insulation [31]. | Sintering conditions varied; properties like density, porosity, thermal conductivity analyzed [31]. |

Detailed Experimental Protocols

To ensure reproducibility and provide insight into data collection methods, here are the protocols for key experiments cited in this guide.

1. Protocol for Assessing Thermal Stability of Aerogels This methodology is used to evaluate the change in thermal properties of aerogel materials after high-temperature exposure [29].

- Sample Preparation: Aerogel samples (e.g., Pyrogel-type) are cut to specified dimensions.

- Thermal Treatment: Samples are subjected to heat treatment in a controlled furnace at target temperatures (e.g., 150°C and 250°C) for a defined period (e.g., 1 day).

- Thermal Property Measurement: Post-annealing, thermal conductivity, diffusivity, and specific heat capacity are measured using standardized techniques (e.g., guarded hot plate or heat flow meter).

- Microstructural Characterization: To understand the microscopic reasons for property changes, samples are analyzed using several complementary techniques:

- X-ray Diffraction (XRD): Identifies crystallization and phase changes.

- Differential Scanning Calorimetry (DSC): Measures thermal transitions and heat capacity changes.

- Infrared (IR) & Raman Spectroscopy: Reveals changes in chemical bonding and amorphous structure.

- Data Analysis: Changes in thermal properties are correlated with structural changes observed during characterization.

2. Protocol for Forming and Testing Porous Geopolymers This protocol outlines the synthesis of porous geopolymers via salt activation and foaming, an alternative to traditional alkali activation [30].

- Raw Material Preparation: Ceramic waste (e.g., waste bricks) is processed into a fine powder.

- Activation and Mixing: The precursor powder is mixed with a sodium dihydrogen phosphate solution (salt activator). A foaming agent (e.g., calcium carbonate) and a foaming activator (e.g., citric acid) are added to the slurry.

- Curing and Foaming: The mixture is poured into molds and cured at elevated temperatures (e.g., 80°C), allowing the geopolymerization and foaming reactions to occur simultaneously.

- Property Testing:

- Bulk Density & True Porosity: Measured using geometric volume and mass, or pycnometry.

- Thermal Conductivity: Measured using a thermal conductivity analyzer (e.g., hot disk or heat flow meter).

- Compressive Strength: Determined using a universal testing machine.

- Microstructural Analysis: Scanning Electron Microscopy (SEM) is used to analyze pore morphology and the aluminosilicate-phosphate network.

3. Protocol for Field Testing Insulation Energy Efficiency This method evaluates the real-world performance of insulation materials, particularly in building applications [32].

- Test Structure Construction: Multiple identical, small-scale test rooms are constructed (e.g., on a building rooftop). Their walls are insulated with the material under investigation (e.g., sawdust-clay composite, sawdust-glue, Styrofoam), with one room left uninsulated as a baseline.

- Environmental Control & Monitoring: A constant heating or cooling load is applied inside each room using a controlled system. The external and internal temperatures are monitored.

- Data Collection: The power consumption required to maintain a set internal temperature is recorded for each test room over an extended period (e.g., 22 days) encompassing various weather conditions (sunny, cloudy, rainy).

- Performance Calculation: The energy consumption of the insulated rooms is compared to the uninsulated baseline to calculate the percentage reduction in energy use, directly quantifying the material's impact on energy efficiency.

Heat Transfer Mechanisms in Porous Insulation

The following diagram illustrates the fundamental heat transfer pathways within a porous insulation material like aerogel, which underpins its performance.

Diagram Title: Heat Transfer in Porous Insulation. This diagram visualizes the three primary heat transfer pathways—solid conduction, gas conduction, and radiative transfer—within a nanoporous material. The Knudsen Effect, which is dominant in materials with nanopores like aerogel, acts to suppress the gas conduction pathway, leading to extremely low effective thermal conductivity [14] [28].

The Scientist's Toolkit: Research Reagent Solutions

This table details key reagents, materials, and instruments essential for the synthesis and characterization of advanced insulation materials, as featured in the cited research.

Table 3: Essential Research Reagents and Materials

| Item Name | Function / Relevance | Example Context |

|---|---|---|

| Silica Sol-Gel Precursors | Forms the nanoporous silica network backbone of the aerogel via sol-gel polymerization. | Base material for silica aerogel synthesis [14]. |

| High-Temperature Foaming Agent (e.g., SiC) | Decomposes or reacts at high temperatures to release gas, creating pores in a ceramic matrix. | Used to create closed-pore foamed ceramics from granite and dolomite waste [31]. |

| Salt Activators (e.g., Sodium Dihydrogen Phosphate) | Activates geopolymerization in precursor materials like ceramic waste, an alternative to corrosive alkali activators. | Key component in synthesizing salt-activated porous geopolymers [30]. |

| Fiber Reinforcements (e.g., Glass, Ceramic Fibers) | Enhances mechanical strength and reduces infrared radiative heat transfer in aerogel composites. | Added to aerogel matrix to create fiber-aerogel composites for high-temperature stability [14]. |

| Fourier Transform Infrared (FTIR) Spectrometer | Characterizes the radiative properties (emissivity, transmittance) of materials, crucial for understanding high-temperature insulation performance. | Used to measure how fiber additions reduce radiative heat transfer in aerogel composites [14]. |

| X-ray Diffractometer (XRD) | Identifies crystalline phases and structural changes (e.g., crystallization) in materials after thermal treatment or synthesis. | Used to analyze microstructural changes in aerogels after thermal annealing [29]. |

In the pursuit of energy efficiency across industries from construction to transportation, thermal insulation materials play a pivotal role in controlling heat transfer and reducing energy consumption [33]. However, the long-term performance and durability of these materials are critically compromised by a pervasive and often overlooked factor: moisture absorption [34]. Traditional insulation materials, including fiberglass, cellulose, and mineral wool, inherently struggle with moisture management, leading to significant degradation of their thermal and structural properties over time [1] [2]. This review systematically examines the inherent limitations of traditional insulation materials regarding moisture absorption and degradation, while evaluating how aerogel technology addresses these challenges through its unique nanoporous structure and hydrophobic properties. By comparing experimental data on performance metrics under various environmental conditions, this analysis provides researchers and material scientists with a comprehensive understanding of moisture-induced degradation mechanisms and the potential of advanced aerogel composites to overcome these limitations in demanding applications.

Material Properties and Moisture Sensitivity

Traditional Insulation Materials

Traditional insulation materials dominate markets due to cost-effectiveness and established manufacturing processes, but share fundamental vulnerabilities to moisture:

Fiberglass: Composed of fine glass fibers, this material is prone to moisture retention and compaction over time, significantly reducing its insulating effectiveness when wet [1] [2].

Cellulose: Manufactured from recycled paper products, cellulose insulation readily absorbs moisture unless treated with chemical additives, potentially leading to mold growth and settling that creates thermal bridges [1].

Mineral Wool: While more moisture-resistant than fiberglass or cellulose, mineral wool can still experience performance degradation under prolonged exposure to humid conditions or direct wetting [1] [2].

These materials primarily function by trapping air within their porous structures, but this same porosity becomes a liability when water infiltrates the matrix, as water possesses significantly higher thermal conductivity than air [34].

Aerogel Technology

Aerogels represent a fundamentally different approach to insulation through their nanostructured porous networks, which are typically over 90% air enclosed within a solid scaffold [35]. The material's exceptional properties stem from this unique architecture:

Hydrophobic Composition: Most commercial silica aerogels are chemically modified to create strongly water-repellent surfaces that prevent liquid water infiltration [34].

Nanopore Structure: The extremely small pore size (typically 20-50 nm) significantly restricts capillary action that draws moisture into traditional insulation materials [2].

Moisture Resistance: The hydrophobic nature combined with the nanoporous structure enables aerogels to maintain performance in high-humidity environments where traditional materials degrade [2] [34].

Table 1: Fundamental Properties of Insulation Material Categories

| Material Type | Primary Composition | Moisture Response | Key Limitations |

|---|---|---|---|

| Fiberglass | Fine glass fibers | Prone to moisture retention and compaction | Performance degradation when wet, potential for mold |

| Cellulose | Recycled paper with fire retardants | High moisture absorption, can settle when wet | Requires chemical treatments, may need replenishment |

| Mineral Wool | Basalt rock or slag | Absorbs moisture over time, especially if damaged | Heavy, requires precise installation to prevent thermal bridging |

| Spray Foam | Polyurethane or latex compounds | Varies by type (closed-cell highly resistant) | Higher cost, professional installation required, chemical emissions during curing |

| Aerogel | Silica, polymer, or carbon nanostructures | Inherently hydrophobic, minimal moisture uptake | Higher initial cost, specialized application requirements |

Experimental Investigations of Moisture Effects

Standardized Testing Methodologies

Research on moisture degradation typically employs accelerated aging protocols to simulate long-term environmental exposure. Standard experimental approaches include:

Freeze-Thaw Cycle (FTC) Testing: Specimens undergo repeated cycling between sub-freezing and above-freezing temperatures while in hydrated states, per standards such as GB/T 33011-2016 [34]. This procedure evaluates material durability in cold climates where water infiltration leads to repetitive freeze-thaw stress.

Volumetric Water Absorption Measurements: Samples are immersed or exposed to high humidity environments, with weight changes monitored over time to quantify moisture uptake capacity and rate [34].

Thermal Conductivity Assessment: Using guarded hot plate or heat flow meter methods, researchers measure thermal performance before and after moisture exposure to quantify degradation [34].

A typical experimental workflow for evaluating moisture resistance follows this systematic process:

Figure 1: Experimental workflow for evaluating moisture resistance of insulation materials

Comparative Performance Data

Recent investigations have quantified the dramatic differences in how insulation materials respond to moisture exposure. A 2025 study examining aerogel-enhanced cement boards under freeze-thaw conditions demonstrated that incorporating just 3-5% hydrophobic aerogel reduced compressive strength attenuation from 40% to 24% after extensive cycling, while simultaneously suppressing the increase in thermal conductivity by approximately 58% compared to non-aerogel composites [34].

The relationship between moisture content and thermal performance reveals why traditional materials suffer significant functional degradation:

Figure 2: Moisture-induced degradation pathways in traditional insulation materials

Table 2: Quantitative Performance Comparison After Moisture Exposure

| Material | Thermal Conductivity Dry (W/m·K) | Thermal Conductivity Wet (W/m·K) | Compressive Strength Retention After FTCs | Volumetric Water Absorption |

|---|---|---|---|---|

| Fiberglass | 0.030-0.040 [2] | Increases significantly [2] | Degrades over time due to moisture and compaction [2] | High [2] |

| Cellulose | 0.035-0.040 [1] | Can double when saturated | Settles and compacts, reducing effectiveness [1] | Very high without treatments [1] |

| Mineral Wool | 0.035-0.040 [1] | Increases with moisture exposure | Loses integrity with prolonged moisture exposure [2] | Medium-High [2] |

| XPS Board | 0.025-0.035 | Up to 100% increase after 300 FTCs with immersion [34] | ~40% reduction after 400 FTCs [34] | Low, but increases with microstructural damage [34] |

| Aerogel Composite | 0.015-0.020 [2] | Minimal change (0.0055 W/(m·K) increase after FTCs) [34] | 76% retention with 5% aerogel content after FTCs [34] | Very low (hydrophobic) [34] |

Mechanisms of Moisture-Induced Degradation

Thermal Performance Degradation

The primary mechanism through which moisture compromises insulation effectiveness involves the displacement of air within the material matrix. Since water possesses approximately 25 times higher thermal conductivity than stagnant air (0.60 W/m·K versus 0.024 W/m·K), even minimal moisture infiltration significantly increases overall heat transfer [34]. In freezing conditions, this effect intensifies as ice formation further elevates thermal conductivity to 2.2 W/m·K [34]. Research demonstrates that after maximum water absorption, the thermal conductivity of traditional materials like polyurethane foam can nearly double, with even more dramatic increases observed in materials like polyphenolic foam (11.52-fold increase) [34].

Structural Integrity Compromise

Beyond thermal performance, moisture initiates and accelerates several degradation pathways that undermine material structure:

Freeze-Thaw Damage: Repeated freezing and thawing of absorbed water generates internal stresses from expansion and contraction cycles, leading to microcrack formation and propagation that ultimately compromises mechanical strength [34].

Chemical Degradation: In cellulose-based materials, moisture can promote biological growth, chemical breakdown of fire retardants, and acidic conditions that accelerate deterioration [1].

Dimensional Instability: Many traditional insulation materials experience swelling, warping, or settling when exposed to moisture, creating thermal bridges and reducing overall system effectiveness [1].

Research Reagents and Materials for Moisture Resistance Studies

Table 3: Essential Research Materials for Insulation Performance Testing

| Reagent/Material | Function in Experimental Protocols | Application Context |

|---|---|---|

| Hydrophobic Silica Aerogel | Primary insulating component with moisture resistance | Modified composite development, typically 3-5% by weight [34] |

| Cementitious Binder | Inorganic matrix for composite samples | Aerogel-cement board fabrication [34] |

| Expanded Polystyrene (EPS) | Lightweight aggregate providing thermal resistance | Base material for aerogel-enhanced insulation boards [34] |

| Freeze-Thaw Chamber | Environmental simulation of seasonal temperature cycling | Accelerated aging studies per GB/T 33011-2016 [34] |

| Guarded Hot Plate Apparatus | Standardized thermal conductivity measurement | Performance evaluation before/after moisture exposure [34] |

| Water Immersion Tank | Saturation conditioning of test specimens | Volumetric water absorption measurements [34] |

The experimental evidence clearly demonstrates that moisture absorption represents a fundamental limitation of traditional insulation materials, leading to significant deterioration in both thermal performance and structural integrity over time. Aerogel technology, with its inherent hydrophobicity and nanoporous architecture, offers a promising solution to these challenges by maintaining stable thermal properties even under demanding environmental conditions. While cost considerations currently limit widespread adoption, ongoing advancements in manufacturing processes—including ambient pressure drying and bio-based precursors—are progressively improving the economic viability of aerogel composites [36] [35]. For researchers and material scientists, these findings highlight the importance of continued investigation into hybrid materials that leverage the moisture resistance of aerogels while optimizing for specific application requirements across construction, transportation, and industrial sectors.

Synthesis, Processing, and Cutting-Edge Applications Across Industries

Aerogel technology represents a revolutionary advancement in the field of insulation materials, offering exceptional thermal performance that significantly surpasses traditional options like fiberglass, foam, or mineral wool. The manufacturing of aerogels centers on two critical processes: the sol-gel reaction, which builds the material's foundational nanoporous network, and the drying technique, which preserves this delicate structure while replacing the liquid solvent with air [37] [38]. The choice of drying method is particularly crucial, as conventional evaporation creates destructive capillary forces that can collapse the fragile gel network, leading to dense, less porous materials known as xerogels [37] [38]. Supercritical drying stands as the benchmark technique for producing high-quality aerogels, effectively eliminating this liquid-vapor interface and the associated damaging forces [37]. This guide provides a detailed comparison of supercritical drying against alternative methods, offering experimental data and protocols to inform researchers and industry professionals in their material selection and process development.

Core Drying Methodologies in Aerogel Production

Three primary drying techniques are employed in aerogel production, each with distinct mechanisms, advantages, and limitations. The following workflows and comparative data illustrate these key differences.

Comparative Performance Data

The selection of a drying method profoundly impacts the final material's properties. The following table summarizes key performance metrics and characteristics for aerogels produced by each primary technique.

Table 1: Comparative Performance of Aerogel Drying Methods

| Property | Supercritical Drying | Freeze Drying | Ambient Pressure Drying |

|---|---|---|---|

| Thermal Conductivity (mW/m·K) | 23.6 [38] | 23.0 [38] | 23.6 [38] |

| Specific Surface Area (m²/g) | 473.8 [38] | 369.4 [38] | 473.8 [38] |

| Porosity (%) | 97.4 [38] | 96.7 [38] | 97.4 [38] |

| Bulk Density (g/cm³) | ~0.06 [38] | ~0.10 [38] | ~0.06 [38] |

| Typical Pore Structure | Nanometric, intact network [37] | Larger pores, potential for ice crystal damage [37] [38] | Nanometric, some shrinkage possible [38] [39] |

| Mechanical Integrity | High, maintains monolithic form [39] | Often brittle, can fracture [39] | Good, but can vary with formulation [38] |

| Surface Chemistry | Native (e.g., hydrophilic for LT-SCD) [39] | Native, unmodified [38] | Hydrophobic (due to modification) [38] [39] |

Experimental Protocols for Drying Methods

Low-Temperature Supercritical Drying (Using CO₂)

Principle: This method utilizes supercritical carbon dioxide (scCO₂), which has a low critical temperature (31.1°C) and moderate critical pressure (7.4 MPa), to remove the pore liquid without creating a liquid-vapor interface [37] [38] [40].

Detailed Protocol:

- Solvent Exchange: Place the synthesized wet gel (e.g., an alcogel like silica hydrogel after solvent exchange with ethanol) into a high-pressure vessel. Gradually displace the original pore liquid (e.g., ethanol) with liquid CO₂ through a series of washes or a continuous flow. This step is critical because water has low solubility in scCO₂ [37] [40].

- Pressurization and Heating: After solvent exchange, seal the vessel. Pressurize it with CO₂ to a pressure above the critical point (typically ~8-10 MPa) and simultaneously heat it to a temperature above 31.1°C (often 40-50°C) [37] [38].

- Holding/Extraction: Maintain the system in this supercritical state. Continuously flow fresh scCO₂ through the vessel for a set period (typically 4-6 hours) to extract and remove all the residual solvent from the gel's pores [37] [40].

- Depressurization: Slowly and controllably release the pressure from the system at a constant rate (e.g., over 1-2 hours) back to atmospheric pressure. This slow release prevents the re-formation of a liquid-vapor interface and the development of stress within the nanoporous structure [37].

- Product Recovery: Once at ambient pressure and temperature, open the vessel and retrieve the resulting aerogel, which retains the original porous network of the wet gel [37].

Freeze Drying

Principle: This technique removes the solvent via sublimation, transitioning it directly from a solid to a gas, thereby bypassing the liquid phase and its associated capillary forces [37] [38].

Detailed Protocol:

- Freezing: Rapidly freeze the wet gel at very low temperatures, typically between -20°C and -80°C. The freezing rate can impact ice crystal size and, consequently, the final pore structure [38] [39].

- Primary Drying: Transfer the frozen gel to a freeze-drying chamber. Apply a vacuum, reducing the pressure below the sublimation point of the frozen solvent (e.g., ~0.014-0.018 mBar for ice). The solvent then sublimates directly from solid to vapor over an extended period, which can be several days [38].

- Secondary Drying (Optional): Some protocols include a secondary drying step with slight heating to remove any bound or unfrozen solvent residues [38].

- Product Recovery: The resulting material, sometimes termed a "cryogel," is collected. It may have a more macroporous structure due to potential ice crystal growth during freezing [37] [38].

Ambient Pressure Drying

Principle: This method allows for evaporation at atmospheric pressure but relies on chemical modification of the gel's internal surface to drastically reduce capillary forces, enabling a "spring-back effect" after initial shrinkage [38] [39].

Detailed Protocol:

- Solvent Exchange: Similar to the first step of supercritical drying, the water in the hydrogel is exchanged for a solvent with lower surface tension, such as ethanol or hexane [38].

- Surface Modification: The alcogel is then treated with a silylating agent like trimethylchlorosilane (TMCS) or hexamethyldisilazane (HMDS) in a non-polar solvent. This reaction replaces surface hydroxyl groups (-OH) with hydrophobic trimethylsilyl groups (-Si(CH₃)₃), making the surface non-wettable [38] [39].

- Controlled Drying: The modified gel is dried under controlled conditions at ambient pressure and moderate temperatures (40-80°C). During drying, the gel initially shrinks but, due to the hydrophobic repulsion between the modified surfaces, the network subsequently re-expands—a phenomenon known as the "spring-back effect" [38] [39].

- Product Recovery: The final aerogel is hydrophobic and possesses a highly porous structure, though it may exhibit slightly higher density and some linear shrinkage (30-50%) compared to supercritically dried samples [38].

The Scientist's Toolkit: Essential Research Reagents & Materials

Successful aerogel production requires specific chemical precursors and reagents for both sol-gel synthesis and the subsequent drying process. The table below lists key materials and their functions.

Table 2: Key Reagents and Materials for Aerogel Research

| Item | Function/Description | Common Examples |

|---|---|---|

| Silica Precursors | Forms the oxide network of the gel via hydrolysis and condensation. | Tetraethyl orthosilicate (TEOS), Tetramethoxysilane (TMOS), Methyltrimethoxysilane (MTMS) [41] [39]. |

| Crosslinkers / Gelation Agents | Promotes the formation of the 3D network from biopolymer solutions. | For bioaerogels: calcium chloride (for alginate), genipin (for chitosan) [40]. |

| Silylating Agents | Imparts hydrophobicity for Ambient Pressure Drying, enabling the spring-back effect. | Trimethylchlorosilane (TMCS), Hexamethyldisilazane (HMDS) [38] [39]. |

| Drying Media | Fluid used to displace pore liquid without collapse. | Supercritical CO₂ (for LT-SCD), Ethanol/Methanol (for HT-SCD) [37] [38] [40]. |

| Reinforcement Fibers/Scaffolds | Integrated into the gel to enhance mechanical strength and reduce brittleness. | Glass fibers, Mullite fibers, polymer scaffolds [41] [37]. |

Discussion: Comparative Analysis and Application Outlook

The data reveals that while supercritical drying produces aerogels with the most exceptional and reproducible properties, recent advances in ambient pressure drying have narrowed the performance gap significantly [38]. The choice of method involves a multi-faceted trade-off.

Performance vs. Practicality: Supercritical drying (especially LT-SCD with CO₂) remains the "gold standard" for research requiring the highest possible surface area and most intact pore structure, making it ideal for applications in catalysis, sensing, and high-performance insulation [37] [39]. However, its high capital cost, energy intensity, and safety requirements for high-pressure equipment are significant barriers to scaling [38]. Ambient pressure drying offers a compelling alternative for cost-sensitive and large-volume applications, such as building insulation and some industrial uses, where its slightly higher density is an acceptable trade-off for drastically lower production costs and easier scalability [12] [38]. Freeze drying occupies a niche, particularly suitable for temperature-sensitive materials (e.g., biopolymer-based bioaerogels) and applications where larger pores are acceptable, such as in acoustic insulation [12] [38] [40].

Material and Environmental Impact: The surface chemistry of the gel precursor directly influences the success of the drying method. For instance, gels made from methyltrimethoxysilane (MTMS) are inherently hydrophobic and better suited for ambient pressure drying, while those from TEOS are hydrophilic and may require surface modification or supercritical drying to achieve optimal properties [39]. From a sustainability perspective, the environmental impact of these methods varies widely. Life-cycle assessments indicate that freeze drying generally has the lowest global warming potential (4.41-9.90 kg CO₂eq), while supercritical drying has the highest (23.6-164.9 kg CO₂eq), primarily due to its high energy demands [38]. The development of ambient pressure drying and the use of bio-based precursors are key trends aimed at improving the sustainability of aerogel production [12] [40].

Within the broader thesis of aerogel technology versus traditional insulation, the manufacturing process—specifically the drying method—is a critical determinant of both material performance and commercial viability. Supercritical drying produces materials with unparalleled insulating performance per unit thickness, a decisive advantage over traditional materials like fiberglass or foam in space-constrained applications. However, the ongoing maturation of ambient pressure drying is the key development that promises to bridge the gap from a high-priced laboratory curiosity to a broadly adopted industrial and construction material. Future research will continue to optimize these drying protocols, reduce their environmental footprint, and tailor them for novel aerogel compositions, further solidifying aerogel's role as a next-generation insulation material.

Aerogel, a nanoporous solid material composed of over 90% air, possesses an exceptionally low thermal conductivity, making it one of the most effective insulating materials known [42] [43]. Its performance stems from a structure where heat transfer is severely limited by nanopores that restrict gas molecule movement and a solid skeleton that elongates the heat transfer path [44]. However, the pristine, monolithic silica aerogel is brittle and fragile. To overcome this for practical applications, aerogels are integrated into various functional forms, including blankets, panels, plasters, and composites, each designed to enhance durability and facilitate integration into different systems [35] [4]. This guide objectively compares these aerogel form factors, providing researchers and scientists with experimental data and methodologies essential for evaluating their performance against traditional insulation in advanced research and development contexts.

Comparative Analysis of Aerogel Form Factors

The integration of aerogel into different matrices creates products with a unique balance of properties. The following table provides a quantitative comparison of the primary aerogel-enhanced forms available to researchers and industrial applications.

Table 1: Performance Comparison of Aerogel Form Factors and Traditional Materials

| Form Factor | Typical Composition | Thermal Conductivity (W/m·K) | Key Characteristics | Primary Applications |

|---|---|---|---|---|

| Aerogel Blanket | Silica aerogel infused in fiber matrix [35] [4] | 0.013 - 0.024 [42] [4] [43] | Flexible, hydrophobic, good handling strength [2] [4] | HVAC duct insulation, industrial piping, building envelopes [2] [35] |

| Aerogel Panel | Aerogel composite core with facing materials [1] | ~0.015 [2] | Rigid, high structural integrity, slim profile [2] [1] | Space-constrained building walls, roofs, and floors [2] [1] |

| Aerogel Plaster | Aerogel particles mixed into render/grout [35] | Information missing | Applied like mortar, combines thermal insulation and coating | Interior wall coatings, historical building retrofits |

| Aerogel Composite (e.g., Fiber) | Aerogel particles/polymers in textiles [35] [43] | 0.017 - 0.020 [43] | Flexible, breathable, excellent thermal retention [43] | High-performance apparel, technical textiles, protective gear [35] [43] |

| Fiberglass Batts | Fine glass fibers | 0.030 - 0.040 [2] | Cost-effective, non-combustible, prone to gaps [2] [8] | Residential wall and attic insulation [1] |

| Spray Foam | Polyurethane or latex | 0.025 - 0.030 [42] | Expands to seal air leaks, high R-value, complex installation [1] [45] | Sealing irregular cavities, wall and roof insulation [1] [8] |

| Mineral Wool | Stone or slag fibers | 0.030 - 0.040 (comparable to fiberglass) [2] | Fire-resistant, soundproofing, heavier [1] | Fire-stopping, high-temperature industrial insulation [1] |

Aerogel blankets, one of the most common forms, integrate silica aerogel with a reinforcing fibrous matrix, creating a flexible, durable, and hydrophobic insulation felt [35] [4]. In contrast, aerogel panels provide a rigid solution for applications demanding structural integrity and a slim profile, often incorporating facers to enhance vapor resistance and mechanical strength [2] [1]. Aerogel composites represent a broader category, including materials like aerogel-enhanced fibers or textiles. These incorporate aerogel particles into polymers or fabrics, yielding flexible materials with high thermal retention for apparel [43] or other specialized composites for technical applications [35]. The plaster or render form factor, where aerogel particles are mixed into a binder, allows for easy application as a thermal coating, which is particularly useful for retrofitting buildings where altering the interior space is not feasible [35].

Experimental Protocols for Thermal Performance Evaluation

Evaluating the thermal properties of insulation materials requires standardized, reproducible methods. The following sections detail two primary experimental protocols for measuring thermal conductivity.

The Heat Flow Meter (HFM) Method

The HFM method is a standard steady-state technique for determining the thermal conductivity of flat slab insulating materials, including aerogel blankets and panels, following ASTM C518-15 [4].

Protocol:

- Sample Preparation: Cut the aerogel blanket or panel to fit the specific dimensions of the HFM apparatus plates.

- Instrument Calibration: Perform a preliminary test using a known standard reference material to calibrate the instrument's heat flux transducers.

- Mounting: Place the specimen between the HFM's parallel plates. The upper plate will automatically adjust to the sample's thickness using digital encoders.

- Establishing Steady State: Set the plates to distinct, constant temperatures (e.g., 10°C and 30°C) to create a steady-state, one-dimensional heat flux through the sample.

- Data Collection: The instrument records the heat flux, the temperature difference across the sample, and the sample thickness.

- Calculation: Thermal conductivity (λ) is calculated based on Fourier's law of heat conduction using the calibration data, plate temperatures, and thickness measurement [4]. The reported accuracy for this method is typically better than 3% [4].

The Protective Heat Flow Meter Device (PHFMD) for Varied Conditions

For testing under non-ambient conditions, a modified setup like the Protective Heat Flow Meter Device (PHFMD) can be used. This apparatus allows for the measurement of thermal conductivity across a range of temperatures and pressures, which is crucial for characterizing performance in extreme environments [44].

Protocol:

- Performance Characterization: Prior to testing, analyze the sample's microstructure using techniques like Scanning Electron Microscopy (SEM) and N₂ Adsorption-Desorption to determine parameters like pore size distribution and specific surface area.

- Model Selection: Select mathematical models for the different components of thermal conductivity (gas, solid, radiation, coupling).

- Controlled Testing: Place the sample in the PHFMD and expose it to a range of temperatures (e.g., from 293 K to 1273 K) and pressures (e.g., from low vacuum to above atmospheric). The heat flow and temperatures are measured at each set point.

- Model Modification: The experimental data is used to modify and calibrate the theoretical decoupling models, particularly for the solid and radiation thermal conductivities (λs and λr), to account for the influence of micro-scale additives and real-world nanostructures [44].

The Scientist's Toolkit: Key Research Reagents and Materials

Research and development in aerogel form factors require specific materials and analytical tools. The following table details essential items for experimental work in this field.

Table 2: Essential Research Reagents and Materials for Aerogel Insulation Studies

| Item Name | Function/Application | Relevance to Research |

|---|---|---|

| Silica Aerogel Precursors (e.g., MTMS) | Base materials for synthesizing silica aerogel matrices [35]. | Fundamental for creating and modifying the nanoporous aerogel structure. |

| Reinforcing Fibers (e.g., glass, polyester) | Provide mechanical support within aerogel blankets and composites [35] [43]. | Critical for studying the trade-offs between thermal performance and mechanical durability. |

| Heat Flow Meter (HFM) | Measures thermal conductivity of flat slab materials per ASTM C518 [4]. | The primary instrument for standardized, steady-state thermal performance evaluation. |

| Protective HFM Device (PHFMD) | Measures thermal conductivity under extreme temperatures and pressures [44]. | Essential for characterizing material performance in non-ambient, application-specific conditions. |

| Scanning Electron Microscope (SEM) | Characterizes the micro-nano porous structure and morphology of aerogel samples [44]. | Key for correlating material microstructure with macroscopic thermal properties. |

Performance Data and Comparative Analysis

The superior thermal performance of aerogel form factors is quantitatively clear when compared to traditional insulation. Aerogel blankets and panels typically possess thermal conductivities between 0.013 and 0.016 W/m·K, significantly lower than fiberglass (0.030-0.040 W/m·K) and spray foam (0.025-0.030 W/m·K) [2] [42]. This translates to achieving the same thermal resistance (R-value) with a much thinner layer, a critical advantage in space-constrained applications [2] [1].

Experimental data from controlled tests highlights this performance gap. For instance, in a test at -20°C with a 5 m/s wind speed, a 3mm layer of aerogel fiber maintained an internal temperature of +15°C, while the same thickness of premium down insulation managed only +8°C [43]. Beyond thermal metrics, aerogels offer complementary properties vital for industrial and scientific applications. They are inherently hydrophobic, resisting moisture absorption and preventing the degradation in performance and mold growth associated with wet traditional materials like fiberglass and cellulose [2] [43]. Furthermore, they are non-combustible and can withstand extreme temperatures without degrading, unlike many foam plastics [2] [35].

Aerogel form factors—blankets, panels, plasters, and composites—offer a suite of high-performance insulation solutions that objectively outperform traditional materials in key metrics, most notably thermal conductivity. For the research community, the selection of a specific form factor is a function of the application's mechanical, environmental, and thermal requirements. The experimental protocols and data presented provide a foundation for rigorous, comparative evaluation.

Future research is poised to enhance the accessibility and functionality of these materials. Key focus areas include reducing manufacturing costs through innovations like ambient pressure drying [35], developing more robust and flexible polymer aerogels [35], and creating intelligent hybrid systems. The integration of aerogels with phase change materials or smart sensors could lead to next-generation insulation that dynamically responds to environmental changes, opening new frontiers in energy management for scientific and industrial applications [35] [8].

The global push for electric vehicles (EVs) hinges on solving one critical challenge: ensuring the thermal safety of high-energy-density lithium-ion batteries. Thermal runaway (TR), a chain reaction of internal exothermic processes, presents a severe safety risk, capable of propagating from a single cell to an entire battery pack, resulting in fire or explosion [46] [47]. The core of mitigating this risk lies in advanced insulation materials that can block or delay this heat transfer. Within this context, a clear technological divergence exists between traditional insulation materials and emerging aerogel technology. Traditional materials like polymer foams and fiber mats have been the industry's mainstay, but their performance is increasingly inadequate for next-generation batteries [47]. Aerogels, with their nanoporous structure, represent a paradigm shift, offering an unparalleled combination of ultra-low thermal conductivity, extreme temperature resistance, and lightweight properties [47]. This guide provides an objective, data-driven comparison of these material classes, framing their performance within the broader thesis of an ongoing materials science revolution aimed at making EV batteries inherently safer.

Material Comparison: Performance Metrics and Experimental Data

The selection of insulation material for a battery thermal management system (BTMS) is guided by a set of critical performance metrics. These metrics determine the material's effectiveness in suppressing thermal runaway propagation (TRP), its impact on the overall system's weight and volume, and its long-term reliability.

Quantitative Performance Comparison

The following table summarizes key properties of aerogel versus traditional insulation materials, based on experimental data and manufacturer specifications.

Table 1: Comparative Properties of Insulation Materials for EV Batteries

| Material Property | Silica Aerogel | Polyurethane Foam | Mineral Wool | Fiberglass |

|---|---|---|---|---|

| Thermal Conductivity (W/m·K) | 0.013 - 0.021 [48] [49] | 0.020 - 0.030 [48] | 0.035 - 0.045 [48] | 0.040 - 0.050 [48] |

| Typical Density (kg/m³) | 3 - 150 [47] | 30 - 60 | 20 - 100 | 10 - 50 |

| Operating Temperature Limit (°C) | >1100 (V-0 Flame Retardant) [47] | ~150 (Decomposes) | ~600 | ~540 |

| Required Thickness for Equivalent R-Value | 1x (Baseline) | ~1.5x - 2x [2] | ~2x - 3x [2] | ~2x - 3x [2] |

| Hydrophobicity | Excellent (Contact Angle >135°) [49] | Varies | Poor (Absorbs Moisture) [2] | Poor (Absorbs Moisture) [2] |

Experimental Suppression of Thermal Runaway

The ultimate validation of an insulation material's performance is its ability to suppress TRP in controlled experiments. Recent scientific studies provide quantitative data on the efficacy of aerogel composites.

Table 2: Experimental Results in Thermal Runaway Suppression

| Experiment Focus | Material Tested | Key Experimental Parameters | Results and Findings |

|---|---|---|---|

| TRP Inhibition Efficiency | Fiber/SiO₂ Aerogel Composite [49] | • Thickness: 2-10 mm• SOC: 0%, 50%, 75%, 100%• Thermal Conductivity: 0.021 W/m·K | A 6 mm thickness prevented TRP at 100% SOC. A dynamic risk-matrix model quantified suppression efficiency. |

| Comparative Material Screening | Aerogel Blanket, Stainless Steel, Epoxy Panel, Nickel Foam [49] | Series of experiments on battery module designs. | Aerogel blankets were found to be the most effective at decelerating TRP. |

| Advanced Composite Performance | Paraffin/SiO₂ Aerogel Composite [49] | Thermal Conductivity: 0.051 W/m·K | A 3 mm layer was sufficient to block TRP. |

| Industrial Application | PyroThin (Aspen Aerogels) [46] | Applied as a cell-to-cell barrier. | Repeatedly stopped TRP in cell-to-cell testing, acting as both a thermal insulator and fire barrier. |

Experimental Protocols: Methodologies for Evaluating Insulation Materials

To ensure the reproducibility and scientific rigor of the data presented, this section outlines the detailed experimental methodologies employed in key studies.

Protocol 1: Synthesis and Characterization of SiO₂ Aerogel Composites

This protocol is based on the work of Huang et al., which focused on preparing a low-cost, high-performance aerogel composite [49].

- Objective: To synthesize a fiberglass-reinforced silica aerogel composite and characterize its physical, thermal, and hydrophobic properties.

- Materials Preparation:

- Sol Preparation: A silica sol is prepared using a silica precursor (e.g., tetraethyl orthosilicate) under controlled pH and temperature conditions.

- Fiberglass Matrix: A fiberglass mat is used as a reinforcing scaffold to improve the mechanical durability of the final aerogel composite.

- Drying Process: The gel, formed within the fiberglass network, is dried via ambient pressure drying. This is a critical step, as it is a more cost-effective and scalable alternative to supercritical drying. Surface modification agents are used prior to drying to prevent pore collapse.

- Material Characterization:

- Scanning Electron Microscopy (SEM): Used to confirm the successful incorporation of the silica aerogel into the interstitial gaps of the fiberglass blanket, revealing the nanoscale porous structure.

- Thermal Conductivity Analysis: Measured using a standardized heat flow meter, confirming an ultra-low value of 0.021 W/m·K.

- Hydrophobicity Test: A water contact angle exceeding 135° is measured, demonstrating excellent hydrophobic properties.

- Thermal Stability: Analyzed via Thermogravimetric Analysis (TGA), showing mass loss below 4% and stability up to 300°C.

Protocol 2: Thermal Runaway Propagation Testing